Product Description

◆ Free from siloxane and the risk of silicone oil bleed.

◆ Good thermal conductivity, available in options ranging from 1.0 to 3.0 W/m·K.

◆ Excellent wetting, low thermal resistance, and high extrusion performance.

◆ High softness and compressibility, providing low assembly stress, ideal for delicate and sensitive electronic components.

◆ No cracking or dripping, ensuring good stability in both high and low-temperature environments.

◆ Can be precisely controlled for thickness and shape using automated equipment.

【Applications】

◆ CPU and GPU◆ Data Center and Server

◆ Power Supply Unit (PSU)

◆ Engine Control Unit (ECU)

Properties

| Properties | Unit | AE10-LT | AE20-LT | AE30-LT | Test Method |

|---|---|---|---|---|---|

| Color | - | Gray | Gray | Gray | Visual |

| Thermal Conductivity | W/m·K | 1.0 | 2.0 | 3.0 | ASTM D5470 |

| Thermal Impedance(@30psi) | ℃*in2/W | 0.13 | 0.08~0.09 | 0.06~0.07 | ASTM D5470 |

| Flow Rate(@30cc,90psi) | g/min | 40±10 | 30±10 | 20±10 | - |

| Density | g/cc | 2.0 | 2.5 | 3.0 | Helium Pycnometry |

| Outgassing | % | < 0.5 | < 0.5 | < 0.5 | ASTM E595 |

| Dielectric Constant (@1MHz) | - | 7.5 | 5.5 | 4 | ASTM D150 |

| Operating Temp. | ℃ | -50 ~ 120 | -50 ~ 120 | -50 ~ 120 | - |

【Storage & Transportation】

Store in a well-ventilated, cool, and dry place, away from open flames.This product is non-toxic and should be stored and transported as a non-hazardous material.

【Packaging】

● 30cc ● 300cc【Shelf Life】

12 monthsAbout Us

◆ Founded: 2008

◆ Team: 110 employees

◆ Facility: 5,000㎡

◆ Focus: R&D and production of functional materials

◆ Strengths: Efficient, collaborative team

◆ Achievements: Key supplier to leading global manufacturers

◆ Applications: Telecom, Automotive, Medical, Computing, Industrial , Military

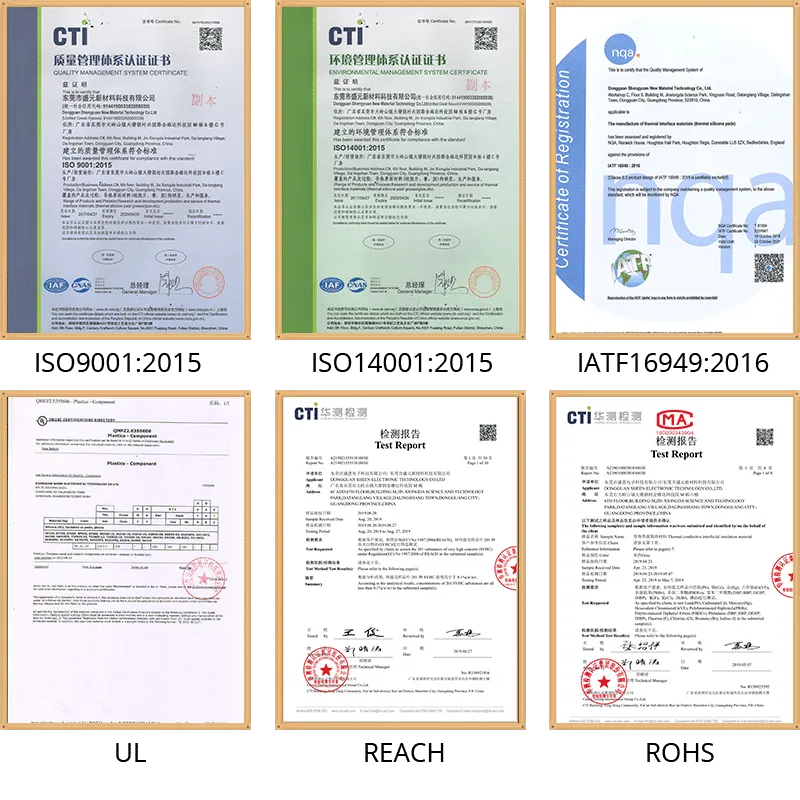

◆ Certifications: ISO9001:2015, ISO14001:2015, IATF16949:2016

Partners

Certifications

English

English

usheenthermal

usheenthermal

.webp)