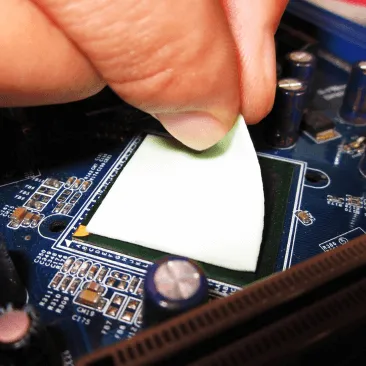

Silicone-free thermal conductive pads are gradually gaining popularity. Taking automobile electronic thermal management as an example, the design and application of silicone-free thermal conductive pads are gradually becoming more widespread. Why is the material of the thermal pad more and more inclined to the type without silicone oil?

Product Features:

1. No silicone component

2. Comply with ROSH standards

3.Good thermal conductivity: 6.0 W / mK

4.High compressibility, soft and elastic, suitable for low pressure application environment

5. Various thickness options are available

Applications:

1. Radiator bottom or frame

2. Set-top box

3. Power supply and vehicle battery

4. Charging pile

5. LED TV LED lamps

6. RDRAM memory module

7. SFP optical module

8. Silicone sensitive applications

9. Miniature heat pipe radiator

10. Medical equipment

The silicone oil-free thermal pad does not contain silicone oil and volatile silicone, and the precision electronic components of the car will not be affected; it has good stability, low viscosity, and can be re-constructed. After high-temperature chemical treatment, no gaseous silicone oil is precipitated, which does not affect the function and service life of components. Generally, precision instruments will consider the problem of volatiles. If you use traditional thermally conductive silicone pads, the evaporation of silicone oil is inevitable. There is no silicone oil thermal pad. This problem has been solved.

English

English

usheenthermal

usheenthermal