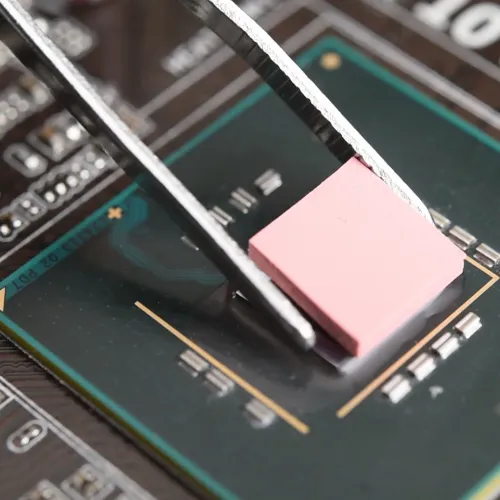

There are many performance advantages of thermally conductive silicone sheet. Firstly, the thermally conductive silicone sheet has high thermal conductivity. Because it is well filled in the gaps between the required heat sink components, the temperature difference between the interfaces is reduced, and the thermal conductivity is greatly improved.

Then the thermally conductive silicone sheet is insulated, and the internal components of many electronic products need thermally conductive materials to insulate, so as not to damage other devices due to electrical conduction.

Secondly, the thermal conductive silicone sheet has good stability and shock absorption effect. The thermal conductive silicone film has a long working life and maintains good stability under long-term pressure and heat without deformation or volatilization. At the same time, due to its strong compressibility, In addition to heat conduction between the devices, it acts as a shock-absorbing pad to avoid damage to the device due to force majeure during transportation or operation, and greatly increase its service life.

Finally, the thermally conductive silicone sheet is easy to operate and suitable for fully automated production mode. The thermally conductive silicone sheet can be cut according to self-requirements. Its self-adhesiveness can facilitate secondary rework. At the same time, the thermally conductive silicone sheet can be shipped in roll mode, which is convenient for enterprise storage management. At the same time, it can be used in automatic coating machines for automated production.

After the above description of the advantages of thermally conductive silicone pads, I will explain the precautions for purchase. Thermally conductive silicone pads are generally customized products. When making an inquiry, customers need to inform the manufacturer of the size, shape, and thermal conductivity of the thermally conductive silicone pad. With the basic requirements of thickness, thickness and hardness, the thermal conductivity material manufacturer will choose whether its own products meet the needs of the customer according to the customer’s demand parameters. If it meets the requirements, it will make a sample and send the sample to the customer for testing. If the test is passed, it will cooperate , Otherwise continue to modify or the customer re-selects its manufacturer.

Customers often find thermal material manufacturers on the Internet or under the recommendation of partners. However, there are mixed good and bad in the thermal material industry. Many manufacturers are small workshops or a single reference. There is no way to ensure the quality of thermal materials, so they are choosing thermal materials for production. When doing business, you must choose those companies that have a certain scale, have their own R&D, production, and sales teams, and have passed the certification of major quality review agencies. It is best to check on the spot.

English

English

usheenthermal

usheenthermal