People later found that the heat conduction effect of installing the heat sink directly on the surface of the heat source was not good, so the heat conduction interface material was filled between the two to make the two close contact and eliminate the air in the gap to reduce the thermal resistance and improve the heat conduction effect. Silicon-free thermal pad is one of many thermal interface materials, and it is also a thermal conductive material that has been given high expectations. So what are the advantages of silicon-free thermal pads that make people feel confident about it?

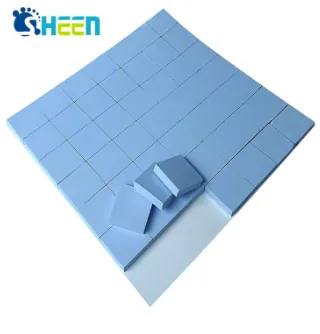

Silicone-free thermally conductive gasket, it is a kind of soft silicone oil-free thermal gap filling material, with high thermal conductivity, low thermal resistance, high compressibility, controllable hardness, no silicone in the operating environment under pressure and heat The volatilization of small molecules prevents the volatilization of small siloxane molecules from being adsorbed on the PCB board, which indirectly affects the performance of the body. The silicon-free thermal pad acts on the gap between the heat source and the radiator/shell. Due to its good softness, it can effectively remove the air from the interface, reduce the thermal resistance of the interface, and improve the thermal conductivity.

There are many advantages of silicone-free thermal pads. One of the main advantages is that there is no silicone oil precipitation. This is also the essential difference between it and thermally conductive silicone pads. Some people say that silicone-free thermal pads are derivatives of thermally conductive silicone pads. In fact, this The argument is not unreasonable. People who use thermally conductive silicone sheets find that silicone oil will precipitate and pollute the circuit. Therefore, based on the idea of non-polluting, silicon-free thermal pads are made on the premise of thermally conductive silicone sheets.

The raw materials used for silicone-free thermal pads are more complex than thermally conductive silicone sheets, and its stability is high. The oil output rate is very low during long-term work, and it can almost be regarded as no oil. Therefore, silicone-free thermal pads do not produce oil. The characteristics of silicon-free precipitation are well-known in the industry. At present, many high-tech industries are born, and their production equipment requires a strict pollution-free environment, so many silicon-free thermal pads are used in these high-precision equipment, silicon-sensitive equipment, and pollution-free environment The industry, as time goes by, the development of the industry also promotes pollution-free environment, so the market prospect of silicon-free thermal pad is very broad.

English

English

usheenthermal

usheenthermal