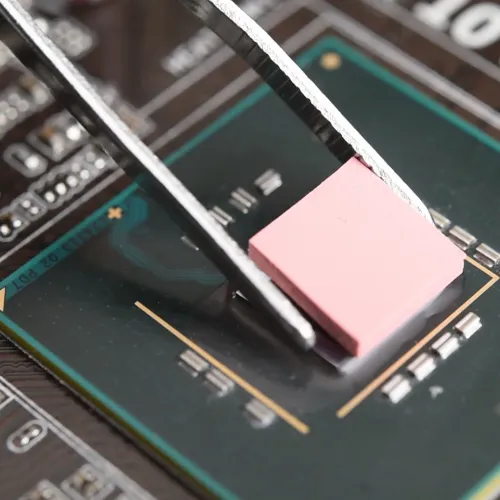

Thermal conductive silicone is a kind of silicon resin as base material, add heat resistance, thermal conductivity materials gap filling thermal conductive gaskets, it have the high thermal conductivity, low interface thermal resistance, insulation, compressibility, and so on characteristics, because of its soft hardness, make its can be realized under the condition of low pressure the small heat resistance, and eliminate interface between air and full fill the contact area between the rough surface, improve the heat conduction effect of contact surface.

Because of its good filling effect, thermally conductive silicone sheet can effectively conduct the heat from the heat source to the shell, and thermally conductive silicone sheet has good compressibility and elasticity, which can be a good shock absorber.

In the procurement process of thermally conductive silicone sheet, in addition to the necessary parameters such as thermal conductivity coefficient, thermal resistance, thickness and special shape, engineers often pay attention to the volatilization of small molecules in thermally conductive silicone sheet. So why should we pay attention to the volatilization of small molecules in thermally conductive silicone sheet?

First used a thermal conductive silicone piece of all know thermal conductive silicone piece use after a period of time will inevitably have the phenomenon of oil, and thermal conductive silicone film have the phenomenon of oil belongs to the normal case, because most of the thermal conductive silicone piece of production process is the silicone oil and thermal conductivity, heat resistance, insulation materials mixed in certain proportion, through the specific machines refined but become, product more, no less, there will be some free in small molecules exist, not completely mixed in the heated and pressurized environment for a long period of time, will slowly precipitation with siloxane small molecules, and then back into the presence of the silicone oil.

Focus on thermal conductivity of silicon sheet small molecule volatile mainly thermal conductive silicone yield efficiency and its relevant, the above also shows that the thermal conductive silicone slice spiral can affect the operation of equipment and high reliability, so to control the yield efficiency, so demands attention thermal conductive silicone pieces of small molecule volatile situation, so as to more accurately understand the thermal conductive silicone oil situation.

English

English

usheenthermal

usheenthermal