It is necessary to apply a thin layer of thermally conductive material to effectively fill the gap between the electronic component and the radiator, so that the two can be in close contact and improve the heat transfer efficiency. The thermally conductive material here is a thermal gel among many thermally conductive materials, and it is also a highly applicable one.

thermal gel is a kind of gel that uses silicone resin as the matrix, adds thermally conductive fillers and bonding materials in a certain proportion, and is processed through a special process. In the industry, it is also known as thermal conductive silica gel mud and thermal conductive mud. It has high thermal conductivity, low thermal resistance and good thixotropy. It has become an ideal material for applications with large gap tolerances. It is filled between the electronic components that need to be cooled and the radiator/shell to make close contact and reduce Thermal resistance can quickly and effectively reduce the temperature of electronic components, thereby prolonging the service life of electronic components and improving their reliability.

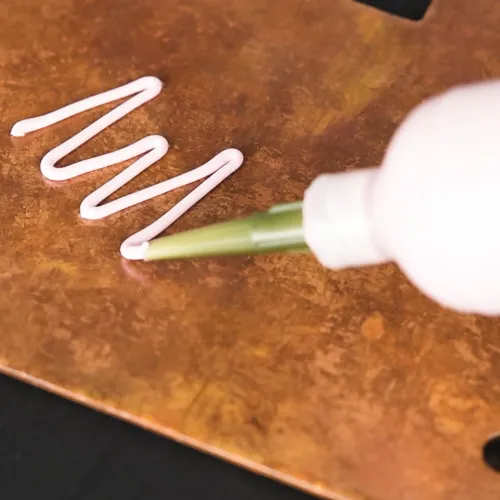

Why is the applicability of thermal gel very strong? Thermally conductive gel has excellent thermal conductivity. Thermally conductive silicone sheets and thermally conductive gels with the same thermal conductivity have better thermal conductivity, and they can effectively cover the gaps. The thermal conductive gel is different from the thermal conductive silicone sheet. It does not require die cutting, and may be customized according to the shape and size of the product. As long as the thermal conductivity and product model are determined, only a single category is required for storage and storage management. Very convenient. And the thermal gel is shipped in a syringe type, which can be applied to automated dispensing and meet the needs of modern automated production.

More importantly, thermally conductive gel can meet the needs of many different occasions. Thermally conductive silicone sheet is a common thermal conductive material on the market, but it is a bit weak in the face of some irregular or large areas. The glue can be customized according to requirements, so the applicability will be stronger.

English

English

usheenthermal

usheenthermal