In reality, two solid surfaces that are in contact with each other, the actual contact between the two is some discrete areas, and the other non-contact interfaces are filled with air, and the heat will be subjected to additional resistance when passing through. This is the explanation of the contact thermal resistance and why heat dissipation The efficiency of the module does not meet expectations in practice.

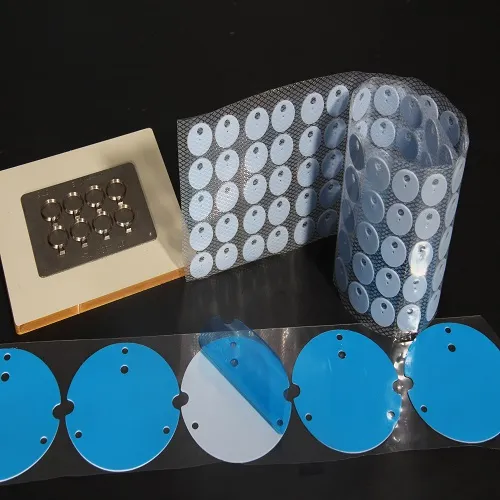

Then, according to the influence of contact thermal resistance on heat and the research on thermal conductive materials, a material specially designed for heat conduction of equipment - thermal interface material was developed. Thermal interface material can effectively reduce the contact thermal resistance between the heat source and the heat dissipation module, and improve both Contact area, thereby improving the heat dissipation effect. Thermal interface material is one of the general names of thermally conductive materials, and there are many types, such as thermally conductive silicone sheet, thermally conductive silicone cloth, thermally conductive phase change sheet, silicon-free thermally conductive pad, carbon fiber thermally conductive pad, thermally conductive Gel, thermal grease, etc., provide a good heat dissipation solution for people's heat dissipation needs.

English

English

usheenthermal

usheenthermal