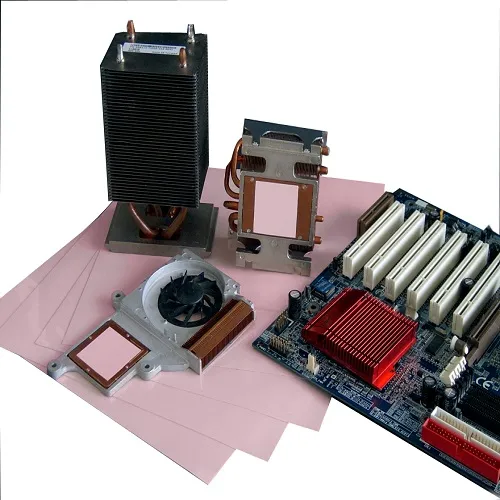

In order to solve this problem, people fill a material called a thermal interface material between the radiator and the heat source. There are many types of heat dissipation interface materials. Common heat dissipation interface materials such as thermal conductive silicone grease, thermal conductive silicone sheet, and silicon-free Thermally conductive gaskets, thermally conductive phase change sheets, thermally conductive insulating sheets, thermally conductive gels, thermally conductive wave absorbing materials, carbon fiber thermally conductive gaskets, etc. Of course, the thermal interface materials are more than these, and some specific environments use thermal interface materials.

The function of the thermal interface material is to fill the gap in the required interface and remove the air in the gap, thereby reducing the contact thermal resistance between the two, thereby improving the heat conduction efficiency, thereby improving the heat transfer rate between the heat source and the heat sink. Auxiliary materials, but its role is very important. With the development of science and technology, the power of equipment is getting higher and higher, and the demand for heat dissipation is also higher, which makes the application range of thermal interface material wider.

English

English

usheenthermal

usheenthermal