The thermal interface material fills the gap between the heat sink and the heat source, fills the gap and removes the air in the gap, thereby reducing the contact thermal resistance between the two. What is the contact thermal resistance? In reality, two solid surfaces that are in contact with each other, the actual contact between the two is some discrete areas, and the other non-contact interfaces are filled with air, and the heat will be subjected to additional resistance when passing through, which is the contact thermal resistance. The higher the contact thermal resistance, the greater the resistance to heat transfer between the two, and the worse the heat dissipation effect, so a thermal interface material needs to be used.

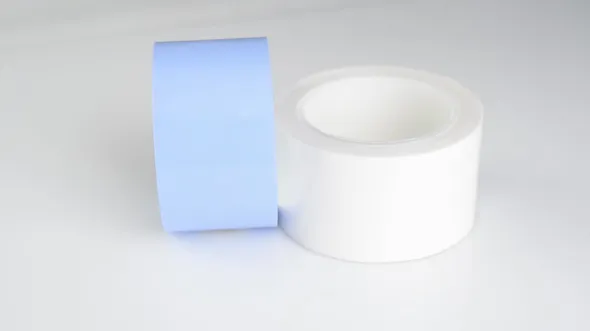

There are many kinds of thermal interface materials, such as silicone thermal pads, silicon-free thermal pads, thermally conductive phase change materials, thermally conductive silicone cloth, thermally conductive wave absorbing materials, thermally conductive gels, thermally conductive silicone grease, carbon fiber thermally conductive pads, etc. In addition to the radiator, the thermal interface material is also indispensable to guide the heat inside the device to the outside. The thermal interface material can allow the radiator to exert its own power, thereby ensuring that the machine and equipment operate within a suitable temperature range.

English

English

usheenthermal

usheenthermal