The heat conduction effect in the air is very poor, and the heat will be resisted when the heat is transferred between the two plane gaps, reducing the heat transfer rate, so it is necessary to use a thermally conductive material to fill the gap between the interfaces and remove the air in the gap, thereby reducing the contact thermal resistance. , so as to improve the heat conduction efficiency.

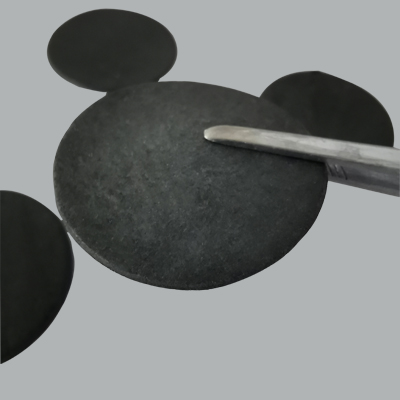

Carbon fiber thermal pad is a new type of thermal conductive material. Its biggest feature is that it has an ultra-high thermal conductivity, which can meet some equipment cooling solutions that have extremely high requirements for heat dissipation. Specifically, carbon fiber thermal conductive pad is a thermal conductive pad made of carbon fiber silicone as raw material and added with thermally conductive and temperature-resistant materials. Since this product uses carbon fiber as raw material, its thermal conductivity can exceed that of copper, and it has good thermal conductivity excellent mechanical properties, electrical conductivity and excellent thermal and radiation heat dissipation capabilities.

English

English

usheenthermal

usheenthermal