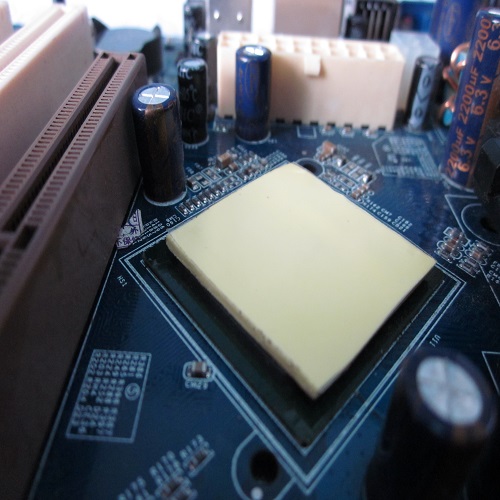

Although thermal conductivity interface material is a kind of heat dissipation auxiliary material, but plays an important role in the entire heat dissipation coefficient, there is a gap between the heating device and the heat dissipation device in the electrical equipment, air is a bad conductor of heat, heat conduction between the two will be subject to air resistance, so the heat conduction speed will be reduced, thus affecting the heat dissipation effect.

Thermal conductive interface material is coated in the equipment between the heating device and the heat dissipation device and reduce the contact thermal resistance of the material, the role of thermal conductive interface material is to fill the interface gap, eliminate the air in the gap, so as to reduce the contact thermal resistance between the two, so that the heat can be quickly transmitted to the heat dissipation device, and the higher the power of the equipment, the higher the heat generated. Therefore, the reason why the high thermal conductivity interface materials are used.

English

English

usheenthermal

usheenthermal