Although the outdoor communication cabinet is larger than the consumer electronic equipment, it is still relatively sealed, and the air is a poor conductor of heat. The heat conduction effect in the air is very poor, so it is impossible to rely on the heat source to dissipate the heat outward. Yes, so the common heat dissipation method is to form a cooling system through heat pipes, heat sinks and fans.

In addition to the cooling system, there is another problem that comes to mind. The contact sheet of the cooling system is bonded to the surface of the heat source, but there is a gap in the bonding interface, so the air still hinders the heat conduction speed between the two, and the application of heat-conducting materials is very important. Good solution to this problem.

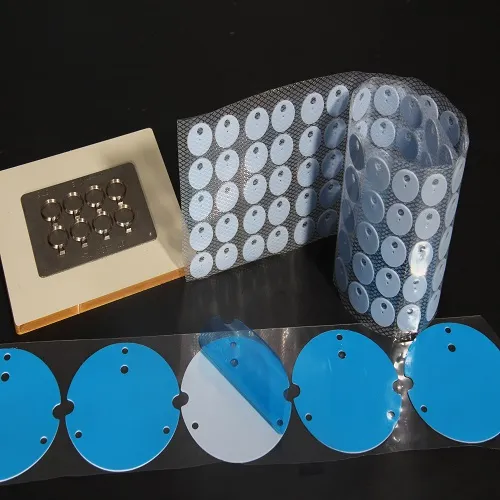

Thermally conductive material is a general term for materials that deal with the contact thermal resistance between heat source components and heat dissipation devices. Thermally conductive materials include solid sheets and semi-flowing pastes. By filling the gap between the heat dissipation device and the heat source, the air between the interfaces is eliminated to This reduces the contact thermal resistance between the two, thereby improving the heat dissipation effect of the cabinet. Although the heat-conducting material accounts for a small proportion of the outdoor communication cabinet, it has little effect at all, providing a guarantee for the normal operation of the outdoor communication cabinet.

English

English

usheenthermal

usheenthermal