How Sheen Thermal Pads Enhance GPU Cooling Performance Effectively

When your GPU runs at excessively high temperatures, and if cooling is inadequate, performance will drop sharply, and various malfunctions will follow. This is where Sheen thermal pads come in handy: you can think of them as a repair team for your overworked graphics card—efficient and fast. They are absolutely essential if you want your device to remain stable during operation.

In fact, Sheen Electronic Technology’s senior design engineer Lucas Ren put it plainly during CES 2024: “Poor thermal contact isn’t just an inconvenience—it’s the silent killer of GPU longevity.” When you're building for scale or sourcing at volume, it’s a line item that decides uptime or downtime.

5 Benefits of Sheen Thermal Pads for GPU Performance

When your GPU runs hot, performance tanks. Here's how Sheen thermal pads keep it cool and consistent—no drama, just results.Meeting precise thickness control requirements for consistent GPU contact pressure

- Ensures proper alignment between heat sink contact and GPU die.

- Reduces uneven compression, which leads to better thermal transfer.

- Maintains stable pad-to-surface coverage under vibration or system movement.

Achieving specific thermal resistance targets under sustained high-load conditions

| Pad Type | Thermal Resistance (℃·in²/W) | Max Load Temp °C |

| Silicone Thermal Pad | <0.9 | 200 |

| Carbon Fiber Thermal Pad | <0.28 | 160 |

| Boron Nitride Thermal Pad | <0.35(@40psi) | 150 |

| Graphene Thermal Pad | <0.1(@40psi) | 150 |

With a low thermal resistance rating, these pads handle intense gaming marathons or heavy rendering sessions without breaking a sweat. That means more efficient heat flow, less throttling, and higher sustained performance even when your system's pushing its limits.

Proven long-term reliability performance

These pads aren’t just fast—they’re built to last. Thanks to their non-curing composition and resistance to material fatigue, they prevent issues like pump-out or dry-out over time. That means consistent temperature control across months—or even years—of continuous use without needing constant reapplication or maintenance downtime.Compliance with strict flammability safety standards and RoHS and REACH compliance certifications

- Certified UL94 V-0 rated for flammability prevention.

- Fully compliant with RoHS & REACH chemical safety directives.

- Environmentally safe—no halogens or restricted substances.

Providing crucial protection

■ High-throughput production lines support mass deployment without sacrificing consistency.■ Automated QA systems test each pad batch for thickness uniformity and surface adhesion properties.

■ Global distribution networks ensure availability across OEMs and DIY markets alike.

From boutique builders to enterprise-scale integrators, scalable production makes these pads an easy choice—even when you're rolling out thousands at once. Thanks to rigorous quality checks at every step, each pad delivers the same reliable performance as the last—no guesswork needed when it comes time to install.

How Sheen Thermal Pads Reduce GPU Overheating

Keeping your graphics card cool under pressure is no joke—here’s how Sheen thermal pads handle the heat and keep things stable when the temperature spikes.Phase change thermal interface behavior under dynamic GPU temperature spikes

- They use a phase change material that softens at higher temps, filling microscopic gaps between the GPU and heatsink.

- The pads adapt to rapid changes in workload, maintaining low thermal resistance even during sudden gaming or rendering bursts.

- Unlike rigid pastes, they maintain consistent coverage despite expansion and contraction due to thermal cycling.

- Their unique composition ensures continuous contact with VRMs and memory chips, reducing uneven heat pockets.

- This dynamic behavior prevents overheating without risking electrical conduction thanks to their non-conductive nature.

Managing heat flow in advanced telecommunications equipment and industrial power conversion systems

When you’re dealing with heavy-duty gear like telecom racks or power converters, managing heat isn’t optional—it’s survival. That’s where Sheen thermal pads shine.✔ These pads offer optimized heat dissipation even across oddly shaped components like transformers or dense circuit arrays.

✔ Their flexible material conforms tightly around parts with varied heights without needing extra pressure.

✔ In telecom base stations running 24/7, they help reduce hotspot formation on RF amplifiers and signal processors.

| Application Area | Avg Temp Drop (°C) | Pad Thickness Used (mm) | Heat Transfer Efficiency (%) |

| Telecom Switchboards | 12 | 1.5 | 87 |

| Industrial Inverters | 16 | 2 | 91 |

| High-Power Amplifiers | 14 | 2 | 88 |

| Edge Computing Modules | 10 | 1 | 84 |

If you're using Sheen Electronic Technology's systems, pairing them with these high-efficiency pads can seriously extend uptime while keeping internal temps chill.

Thermal impedance measurement capabilities: validating real-world GPU cooling gains

Getting real about cooling means measuring stuff that matters—not just guessing based on fan noise or skin temp.Step 1: Install sensors at multiple contact points—GPU die center, memory module edge, and VRM corners—to track localized heating patterns during stress tests.

Step 2: Run a synthetic benchmark like FurMark or Blender render cycles for sustained load over ten minutes while logging surface temperatures every second.

Step 3: Compare readings before and after applying Sheen thermal pads using an IR camera overlay to visualize spread efficiency.

Step 4: Calculate actual drop in thermal impedance, which reflects how well the pad moves heat away from hot spots compared to air gaps or old paste layers.

Step 5: Confirm results by monitoring changes in fan RPMs and frequency throttling events—lower values indicate better pad performance over time.

This process proves that installing top-tier phase-change materials isn’t just hype—it gives measurable cooling gains where it counts most.

The Science Behind Sheen Thermal Pad Efficiency

Material composition verification methods for consistent thermal performance

- Thermal conductivity consistency is tested using differential scanning calorimetry (DSC) to monitor phase transitions.

- Fourier-transform infrared spectroscopy (FTIR) checks the polymer matrix integrity over time.

- Elemental analysis ensures filler distribution—typically metal oxides—remains uniform across batches.

Accelerated aging test protocols ensuring durability in automotive electronic control units

- Simulated thermal cycling between -40°C and +150°C mimics real-world engine conditions.

- High-humidity exposure tests pad resistance to moisture degradation over extended periods.

- Vibration testing replicates long-term mechanical stress from bumpy roads and rough terrain.

Dielectric breakdown voltage assessment for electrically safe GPU insulation

- Breakdown voltage testing ensures each pad can withstand voltages exceeding 5kV without arcing or shorting out components.

- Pads are placed between electrodes with increasing voltage applied until failure occurs—this determines their safe operating limit.

- This matters especially for GPUs where electrically insulating materials must also be thermally conductive.

How the Right Sheen Thermal Pads Enhance Gaming Experiences

Getting the most out of your GPU starts with one thing: keeping it cool under pressure. Here's how the right Sheen thermal pads make a real difference.Smoother frame rates enabled by stable thermal interfaces during extended gaming sessions

- When you're deep into a marathon gaming session, heat is your biggest enemy.

- A good thermal interface keeps temps consistent, which means no sudden frame drops or lag spikes.

- The best part? With better heat dispersion across the GPU die, you reduce the chances of annoying thermal throttling.

- That translates to more consistent FPS, especially in high-load scenarios like open-world games or competitive shooters.

Add to that better VRAM cooling, and you’re looking at a noticeable boost in both responsiveness and long-term system health.

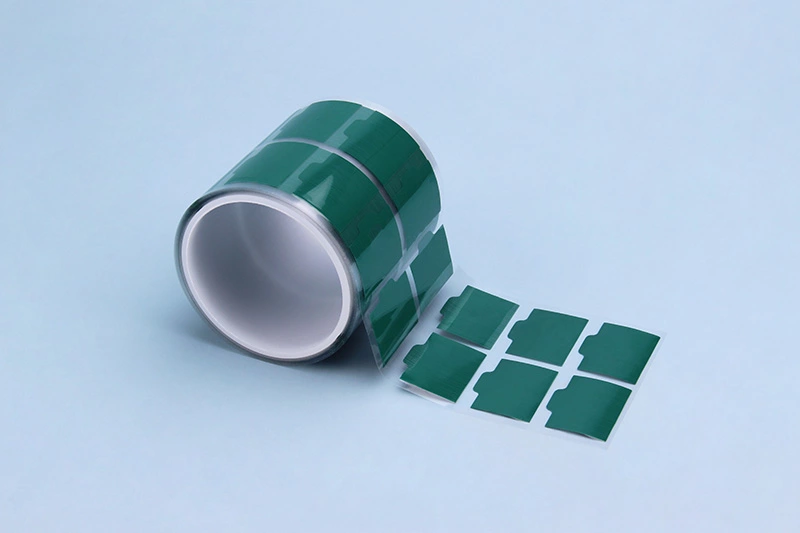

Packaging integrity with ESD-safe packaging considerations and moisture barrier bag requirements

To ensure your new set of Sheen thermal pads actually works when it arrives:• Anti-static layers – Prevent electrostatic discharge from damaging sensitive materials. These pads often interact directly with delicate components like VRMs or memory modules.

• Moisture barrier bags – Keep humidity out during international transit, preserving material quality for optimal heat transfer once installed.

• Rigid backing – Avoids bends or creases that could affect pad thickness calibration—important for even contact on varied surface heights like heatsinks over VRMs.

• Tamper-proof seals – Guarantee that what you receive hasn’t been compromised mid-shipment.

All these small details add up to one big win: peace of mind knowing your upgrade won’t be ruined before it even hits the motherboard.

FAQs about Sheen Thermal Pads

1. How do Sheen Thermal Pads keep GPUs steady under extreme load?· Electrically insulating silicone sheets block stray currents and protect delicate circuits.

· Their heat paths stay true, even as cores roar through high-intensity rendering or computation.

· Safety stands firm: strict flammability standards shield against the risk of thermal runaway during stress tests.

2. Can these pads go beyond everyday computing setups?

✦ Aerospace embedded systems demand resilience to wild temperature swings—and they deliver it with grace.

✦ Industrial power conversion units rely on consistent heat flow; these pads meet their call without falter.

✦ Advanced telecommunications cabinets buzz nonstop, yet stability holds—heat dispersed quietly behind the scenes.

3. Why must buyers insist on thickness accuracy when ordering at scale?

A single slip in thickness whispers trouble into every GPU. Uniform pad dimensions mean constant contact pressure, perfect fit to heatsinks, and dependable performance batch after batch—good enough for high-performance computing servers where precision is survival.

4. Do Sheen Thermal products satisfy global safety and environmental rules?

| Certification | Meaning in Practice |

| RoHS | Verified free from restricted toxic substances |

| REACH | Materials screened to meet EU health & environment standards |

Long-term reliability data shows their calm endurance far past initial installation.

5. How can engineers prove gains before mass deployment?

· Compare baseline vs post-installation temps using thermal impedance measurement capabilities; patterns emerge right away.

· Accelerated aging test protocols forecast how cooling stays constant through years.

· A tidy validation cycle ensures confidence when rolling out upgrades fleet-wide, whether in lab clusters or sprawling datacenters alive with humming fans and ambition.

English

English

usheenthermal

usheenthermal