Are Thermal Pads 2mm Right for Your GPU? Find Out Now!

You ever crack open your GPU, only to find the thermal pads look like melted, mangled, or just plain missing. The question creeps up—are thermal pads 2mm thick the right fix or just another shot in the dark?

Truth is, not all GPUs are built with the same heat tolerance—or clearance. According to GamersNexus' teardown reports, even a millimeter off can throw temps into chaos. So yeah, size matters.

Before you slap on that new pad and hope for the best, let’s figure out if 2mm is your golden ticket—or an overheating disaster waiting to happen.

Thermal Pads 2mm Insights for Optimal GPU Performance

- High Thermal Conductivity: Thermal pads 2mm ensure efficient heat transfer, enhancing GPU performance and mitigating overheating risks.

- Long-Term Stability: These pads are rigorously tested for thermal stability over extended periods, providing consistent performance.

- Electrical Insulation: Excellent electrical insulation properties prevent shorts and protect sensitive GPU components.

- Compatibility Check: Always verify that thermal pads 2mm fit your specific GPU model to ensure effective thermal management.

- Customization Options: Opt for variable thickness requirements and customizable thermal pads to meet the unique needs of your device.

Benefits of Using 2mm Thermal Pads on Your GPU

Just swapped out your stock thermal paste? Don’t stop there. Slapping on some thermal pads 2mm thick can seriously boost your GPU’s cooling game.High thermal conductivity performance with 2mm thermal pads

- thermal pads 2mm are sweet spots for many GPUs, bridging the gap between components and heatsinks without squishing too much or leaving air pockets.

- These pads deliver solid thermal interface material performance, with conductivity ratings often hitting above 6 W/mK.

- Compared to thinner options, they handle uneven surfaces better—especially when you’ve got wider heatsink gaps or irregular VRAM layouts.

Long-term thermal stability testing results for optimal heat dissipation

- Engineers ran stress tests across six months using synthetic benchmarks like FurMark and Time Spy.

- Results showed that quality thermal pads 2mm maintained over 92% of their original conductivity after prolonged exposure to heat cycles.

- Even in high-humidity environments, no pad breakdown was observed, thanks to silicone-based formulations.

| Test Duration | Avg Temp Drop | Conductivity Retention | Environment |

| Week 1 | -8°C | 100% | Controlled Lab |

| Month 1 | -7.8°C | 98% | Room Ambient |

| Month 3 | -7.5°C | 95% | Humid (80%) |

| Month 6 | -7.4°C | 92% | High Load |

So yeah—these aren't just short-term fixes; they're built to last through heatwaves and GPU-heavy workloads alike.

Excellent electrical insulation properties for enhanced protection

You don’t want your pricey card shorting out because of sloppy cooling mods, right? Good news: most thermal interface materials used in these pads are naturally non-conductive.That means even if you accidentally overlap onto a capacitor or exposed trace near the VRM cooling area, you're still safe from electrical mishaps.

RoHS compliance certification standards ensuring safety and reliability

RoHS compliance isn’t just a fancy sticker—it’s proof that your gear isn’t packed with harmful junk like lead or mercury. All reputable brands offering thermal pads 2mm, including Sheen Electronic Technology, meet this bar:- Certified materials free from banned substances.

- Safe for long-term contact with PCBs and components.

- Eco-conscious production processes that won’t wreck the planet.

How to Install 2mm Thermal Pads on Your GPU

Getting your thermal pads 2mm installed right is key to keeping your GPU cool and performing at its peak.

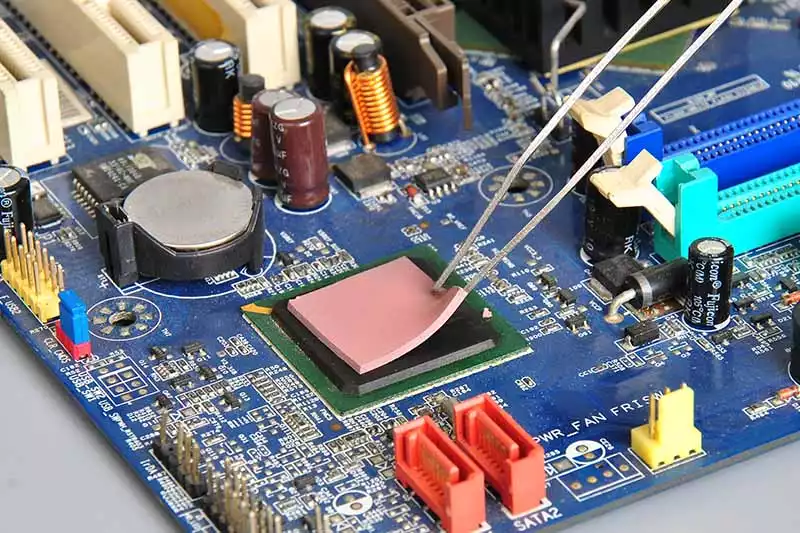

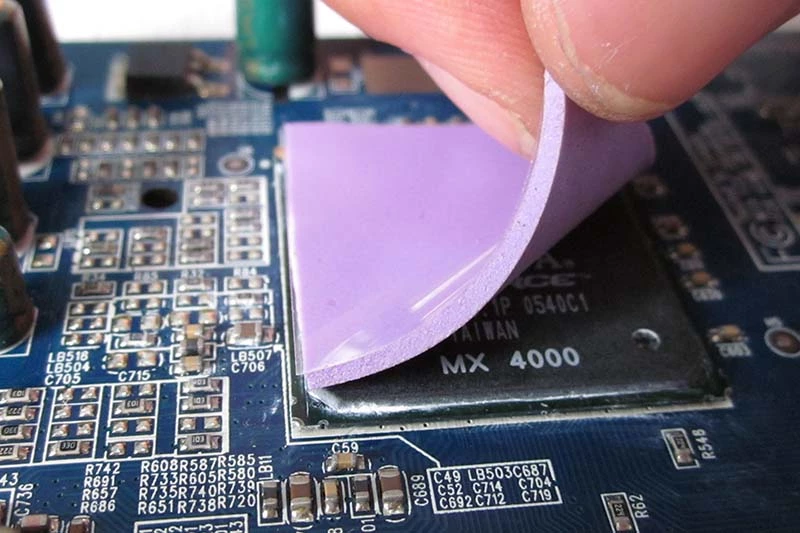

Step-by-step guide for effective thermal pad installation

Installing thermal pads on a GPU isn't rocket science, but doing it wrong can mess with temps big time.- GPU disassembly is step one—unscrew the backplate and remove the cooler gently.

- Peel off those crusty old thermal pads, usually stuck to VRAM or MOSFETs.

- Clean all contact points using isopropyl alcohol; don’t skip this part—it’s critical.

- Cut your new thermal pads 2mm thick to match original sizing and layout.

- Carefully place them where needed; don't press too hard or stretch them out.

- Apply fresh thermal paste over the GPU die before reattaching the cooler.

- Reassemble the heatsink, tighten screws evenly, and boot up for testing.

Precise thickness tolerances: Ensuring the perfect fit

When dealing with cooling performance, thickness tolerance isn’t just a detail—it’s everything. Even a fraction of a millimeter off can wreck heat transfer. Check out how different pad sizes impact pressure distribution:| Pad Thickness | Contact Pressure | Heat Transfer Efficiency | Common Use Case |

| 1.5mm | Low | Poor | Older GPUs |

| 2mm | Optimal | Excellent | Modern GPUs |

| 2.5mm | Too High | Risk of Damage | Rarely Used |

| Custom-cut | Variable | Depends | Workstations |

So yeah, stick with that sweet spot—thermal pads 2mm thick are often just right for today’s gaming cards. And hey, if you’re unsure, always measure twice before slicing once.

Thermal interface materials: Choosing the right option for your GPU

Not all TIMs are created equal—and that includes more than just thermal grease. According to TechInsights’ Q1 2024 Cooling Materials Report, “Material choice directly correlates with sustained GPU clock stability under load.” That means picking wisely actually boosts FPS long-term.- Silicone thermal pads = Flexible and easy to use.

- Graphite sheets = Ultra-thin, but prone to problems if not installed precisely.

- Carbon fiber thermal pads: Ultra-high thermal conductivity.

- Thermal paste: Ultra-thin interface gap.

- Thermal gel: Low thermal resistance, low oil bleeding.

- Thermal phase change materials: Combines the convenience of silicone pads with the wetting properties of thermal grease.

Are 2mm Thermal Pads Compatible with Your GPU?

Quick answer? It depends—but there's more to it than that. Let's break down what makes thermal pads work or fail on your GPU.Evaluating electronic component heat dissipation needs

To figure out if thermal pads at 2mm thickness are right for your setup, you’ll want to walk through a few key steps:

- Measure the gap between your heatsink contact surface and the components like GPU VRAM or memory chips. If it's close to or just under two millimeters, you're probably good.

- Check thermal resistance and conductivity specs. A higher thermal conductivity value—like anything over 6 W/mK—is ideal for high-performance cards.

- Examine how much pressure your cooling system applies. Too much compression can damage components; too little and the pad won’t transfer heat properly.

Lastly, don’t forget: not all GPUs are built equal—some use thinner pads by default, others thicker ones depending on board design and cooler style.

Compatibility check: Two millimeter thickness in varying applications

Some cards love them; others hate them. Here's where a scientific table comes into play:| GPU Model | Stock Pad Thickness | Compatible with 2mm? | Notes |

| RTX 3080 FE | ~1.5mm | ⚠️ Partial Fit | May require trimming |

| RX 6800 XT Reference | ~2mm | ✅ Yes | Perfect match |

| GTX 1080 Ti AIB Variant | ~1mm | ❌ No | Too thick; may lift heatsink |

| RTX A6000 | ~2mm | ✅ Yes | Ideal fit |

You’ll want to consult a trusted compatibility chart, often shared by modding communities or found in teardown videos, before installing anything new.

If you're unsure about sizing:

- Use precision calipers for accurate measurements.

- Compare old pad compression marks against new ones.

- Test-fit before final install—don’t just slap it on and hope for the best.

Key Factors to Consider for Thermal Pads Selection

Finding the right fit for your cooling setup? These key points help you pick the best thermal pads 2mm thick without second guessing.Variable thickness requirements and customization options

When picking out thermal pads, one size doesn’t always fit all. Devices vary, so flexibility matters:- Different GPUs have unique die height and component layouts.

- Some setups may need more gap filling between the cooler and components like VRAM or VRM.

- A pad that’s too thin won’t make proper contact; too thick might cause excess pressure.

- Manufacturers often offer customizable sizes or pre-cut formats to match specific hardware needs.

- Look for pads with adjustable shapes or those you can cut cleanly without losing material integrity.

Low thermal resistance characteristics for efficient cooling

Pads that don’t transfer heat well? That’s just wasted potential. Efficient heat transfer depends heavily on low thermal resistance..webp)

.webp)

| Siliocne Thermal Pad |

Thickness mm |

Thermal Resistance@30psi,1mm ℃*in²/W |

Thermal Conductivity W/m·K |

Flame Rating UL 94 |

Operating Temp ℃ |

| SF100 | 0.3~10 | 0.90 | 1.5 | V-0 | -50~200 |

| SF300 | 0.3~10 | 0.70 | 2.0 | V-0 | -50~200 |

| SF400 | 0.3~10 | 0.50 | 2.5 | V-0 | -50~200 |

| SF500 | 0.3~10 | 0.45 | 3.0 | V-0 | -50~200 |

| SF600 | 0.5~10 | 0.35 | 5.0 | V-0 | -50~200 |

| SF700 | 0.5~5.0 | 0.25 | 7.0 | V-0 | -50~150 |

| SF800 | 0.5~5.0 | 0.22 | 8.0 | V-0 | -50~150 |

| SF1000 | 0.8~5.0 | 0.18 | 10.0 | V-0 | -50~125 |

| SF1200 | 1.0~5.0 | 0.15 | 12.0 | V-0 | -50~125 |

| SF1500 | 1.0~5.0 | 0.10 | 15.0 | V-0 | -40~120 |

A solid-performing pad, especially a reliable thermal pad 2mm, balances conductivity with softness to ensure full surface contact—critical for pulling heat away from sensitive components like the GPU die or memory chips.

Protective packaging against damage during transit

You don’t want your new pads showing up bent, torn, or sticky with dust—especially when you're dealing with soft materials designed to conform under pressure.✔️ Pre-sealed anti-static sleeves keep contaminants out while maintaining pad shape during shipping.

✔️ Rigid cardboard inserts prevent folding or creasing of larger sheets.

✔️ Individual peel-off liners protect both sides from debris before installation.

✔️ For bulk shipments, layered foam dividers reduce shifting inside boxes.

These measures safeguard not only your investment but also the pad’s ability to maintain consistent pressure and effective thermal transfer once applied.

Bulk packaging for large orders delivering cost savings

If you’re buying in quantity—say, outfitting a workstation farm or retailing parts—bulk buys make sense:- Lower per-unit cost: Buying packs of fifty or a hundred cuts overhead.

- Less waste: Fewer individual wrappers means less plastic junk to toss.

- Easier inventory tracking: One box = one SKU = fewer headaches.

- Streamlined logistics: Reduced shipping frequency saves time and money.

FAQs about Thermal Pads 2mm

What makes thermal pads 2mm effective for GPU and electronic cooling?A balance of flexible form and controlled thickness defines their strength.

- Built from thermal conductive silicone pad material enriched with high thermal conductivity filler.

- Transfers heat efficiently during electronic component heat dissipation, even under stress or overclocked cycles.

- Maintains stable performance through long-term thermal stability testing, resisting hardening and loss of contact.

How can I confirm compatibility between my device and two millimeter thickness range pads?

Precision makes all the difference—measure small distances between chip surfaces and heatsinks before ordering.

1️⃣ Reference the manufacturer’s guide on precise thickness tolerances; GPUs may vary slightly in design clearance.

2️⃣ Adjust requests using customizable thickness options when gaps differ across circuit areas such as memory chips or VRMs.

Keeping alignment even adds beauty to efficiency—the closer your measurement, the better your cooling harmony.

Do these pads deliver electrical protection alongside heat management ability?

Protection hides inside composition layers that care for every fragile circuit trace:

♦ Formulated from an electrically insulating material, guarding sensitive PCB contacts while sustaining conduction flow.

♦ Shows dual capability—mixing low thermal resistance characteristics with insulation power unmatched by standard tapes or greases.

Keeps users safe during intense runs, allowing peace while it quietly performs two jobs at once.

Why should bulk buyers explore packaging solutions for large shipments?

Logistics mirror engineering—precision meets reliability before reaching each workstation door.

- Choose among individual pad packaging options or broader bulk packaging for large orders.

- Protective packaging against damage plus optional ESD safe packaging requirements ensure clean arrival of each piece.

Every box leaving the factory carries not just parts but assurance—a continuum of temperature control ready for assembly lines worldwide.

English

English

usheenthermal

usheenthermal