Unlock Superior Heat Management with A High Thermal Conductivity Insulating Sheet

Picture this: a circuit board so hot you could fry an egg on it—yeah, not ideal. That’s where the high thermal conductivity insulating sheet steps in like the unsung hero of modern electronics, quietly saving your chips from meltdown while keeping everything shock-proof and steady under pressure.

Heat is sneaky. It builds up fast, hides in corners, and picks off your components one by one. In EV battery packs or power amplifiers pushing max output, poor heat control isn’t just inconvenient—it’s business-critical. One misstep? You’re looking at warranty claims or worse: recalls.

According to Yole Intelligence's 2023 Thermal Management report, demand for advanced thermal interface materials has skyrocketed by 29% year-over-year—driven largely by EVs and compact consumer tech where every degree counts.

Quick Insights on High Thermal Conductivity Insulating Sheets

- Performance Enhancement: High thermal conductivity insulating sheets significantly improve the heat dissipation in high-power electronic components like power amplifiers and electric vehicle batteries.

- Thermal Management: These sheets revolutionize integrated circuit heat spreading by ensuring even heat distribution, which prevents hotspots and enhances reliability.

- Mechanical Strength: Their good mechanical strength coupled with flexibility ensures longevity and stability, making them suitable for various applications.

- Electrical Insulation: They provide excellent electrical insulation properties, crucial for safely managing high-power devices without risk.

- Custom Formulations: Manufacturers offer competitive pricing with custom material formulations to meet specific application needs.

- Quality Assurance: Rigorous quality control procedures ensure that high thermal conductivity insulating sheets consistently perform under operational conditions.

Unlocking Efficiency with High Thermal Conductivity Insulating Sheets

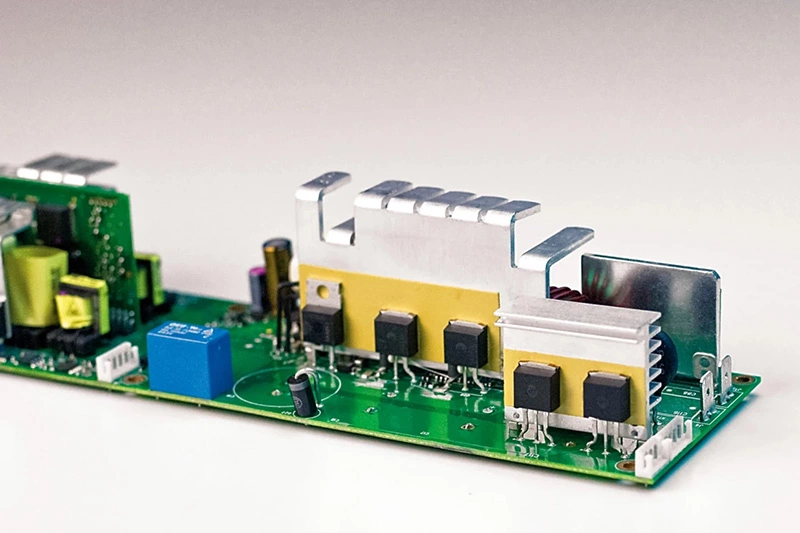

From power-hungry devices to compact microchips, managing heat is key. These high thermal conductivity insulating sheets are changing the game—quietly but effectively.Enhancing Performance in High-Power Electronic Component Cooling

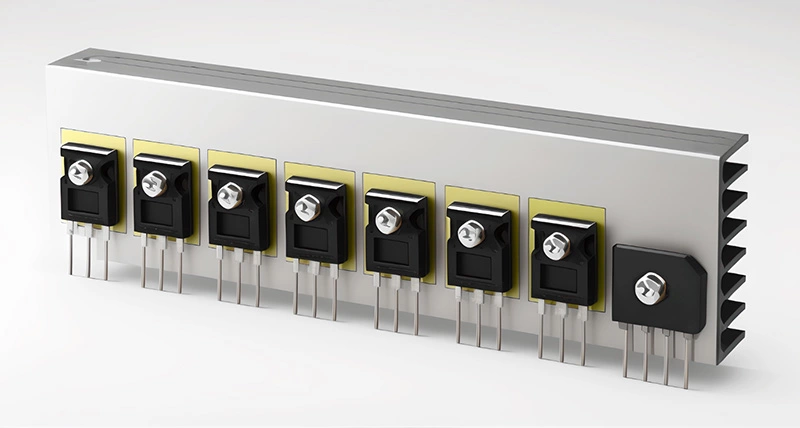

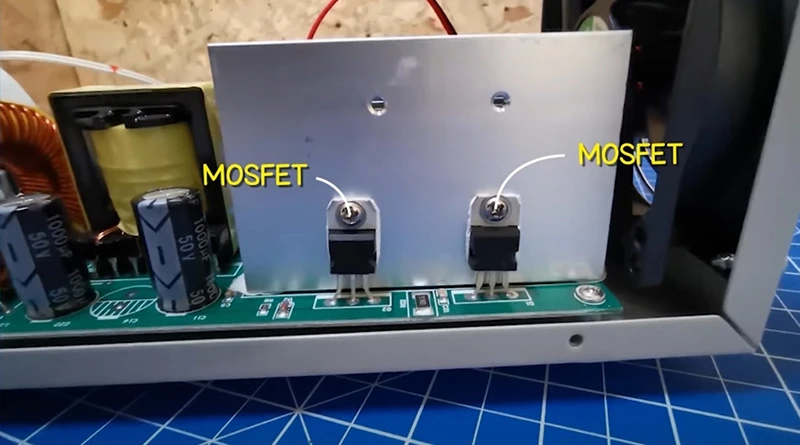

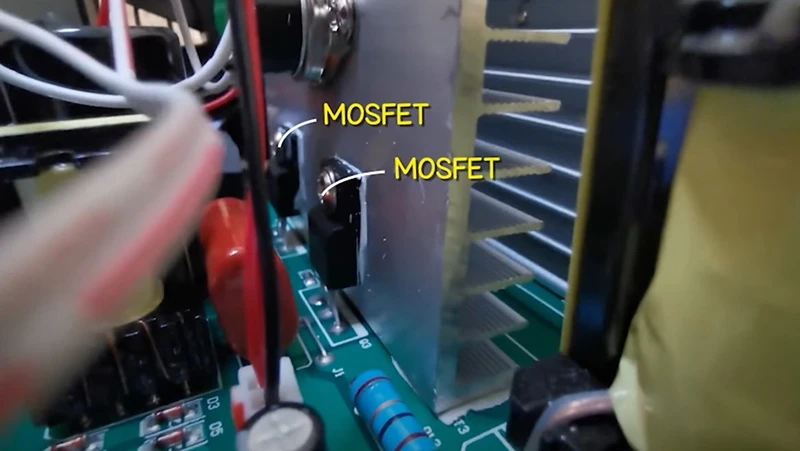

- Boosts cooling efficiency for high-power electronics like EV batteries and telecom amplifiers.

- Reduces thermal resistance between components and heatsinks using thin-layered thermal management materials.

- Minimizes risk of overheating, which improves long-term device performance.

Revolutionizing Integrated Circuit Heat Spreading Methods

Integrated circuits are getting smaller—and hotter. Here's how these advanced materials make a difference:- They distribute heat across the silicon substrate, reducing localized temperature spikes.

- Their low-profile form factor fits into tight microelectronic spaces.

- They're compatible with existing packaging workflows, cutting down on redesign time.

Long-Term Reliability: Evaluating Mechanical Strength Properties

Durability isn’t just about surviving today—it’s about thriving tomorrow too.Short-term performance means nothing if your material cracks or degrades over time under mechanical stress or temperature cycling. A high thermal conductivity insulating sheet must balance flexibility with tensile strength while resisting delamination or warping during use.

This is where composite layering comes into play—each layer supports structural integrity while maintaining top-notch heat transfer capabilities across all operating conditions.

Comparative Mechanical Strength & Thermal Conductivity Data Table

.webp)

.webp)

| Properties | Reinforcement Carrier | Thermal Conductivity (W/m·K) |

Tensile Strength (psi) |

Standard Hardness (Shore A) |

| SC800FG | Fiberglass | 0.8 | 450 | 90 |

| SC900FG | Fiberglass | 2.0 | 450 | 90 |

| SC1000FG | Fiberglass | 3.5 | - | 90 |

| SC2000FG | Fiberglass | 5.0 | - | 90 |

| SC800-PI-2-K4 | Polyimide | 0.9 | - | 90 |

| SC800-PI-2-K6 | Polyimide | 1.1 | - | 90 |

| SC800-PI-2-K10 | Polyimide | 1.3 | - | 90 |

| Test Method | - | ASTM D5470 | - | ASTM D2240 |

*Data based on third-party testing of Sheen Electronic Technology’s multi-layered composite variants

This comparison shows how far we've come from basic plastics toward highly engineered solutions that combine both strength and superior heat transfer properties—perfect for next-gen electronics cooling needs.

Everyday Use Cases for Heat-Conductive Insulators

Let’s break this down by real-life scenarios:

- In electric vehicles? They’re used between battery modules to prevent thermal runaway events during rapid charging cycles.

- In telecom base stations? They keep power amplifiers cool even under continuous transmission loads.

- In consumer laptops? These sheets help avoid CPU throttling by spreading localized heat more evenly than metal foils alone can manage.

How These Sheets Adapt to Diverse Environments

Step-by-step adaptation process:- Step 1: Select material composition based on target application voltage and ambient temperature range.

- Step 2: Customize thickness depending on gap-fill requirements between surfaces like PCBs and chassis walls.

- Step 3: Apply pressure-sensitive adhesive backing if reworkability is needed post-installation.

- Step 4: Integrate into final assembly using vacuum lamination or direct placement methods based on automation level available at production site.

Grouped Benefits Across Application Types

Electrical Safety + Thermal Control:- Prevents electrical shorts.

- Maintains dielectric strength even at elevated temps.

- Ensures consistent heat dissipation.

- Resists cracking under vibration.

- Withstands repeated heating/cooling cycles.

- Retains bonding strength over time due to strong material properties.

- Conforms to uneven surfaces.

- Cuttable into custom shapes without fraying.

- Lightweight alternative to ceramic-based options for many modern systems.

Tuning Material Composition for Targeted Results

Sometimes it’s all about fine-tuning what goes inside the sheet:- Add graphite fillers = higher lateral conductivity for planar applications like IC substrates.

- Use ceramic particles = boost vertical insulation while keeping decent side-to-side transfer.

- Add polyimide film enhances overall electrical insulation performance.

- Add glass fiber as a base material improves the material's cut resistance and mechanical flexibility without sacrificing long-term performance stability.

This versatility makes them not just useful—but essential—in modern electronic design workflows where failure isn’t an option but efficiency always matters most.

4 Benefits of High Thermal Conductivity Insulating Sheets

Discover how high thermal conductivity insulating sheets bring more than just heat management—they pack a punch in safety, durability, and customization.Excellent Electrical Insulation Properties for Enhanced Safety

- High dielectric strength ensures that even under high voltage, the sheet won’t let current sneak through.

- Arc resistance keeps components protected from electrical discharges—no nasty surprises.

- Built-in creepage resistance, helping devices meet strict international safety standards.

- Ideal for power modules, battery packs, and inverters where electrical isolation is non-negotiable.

- The sheets are tested to handle extreme environments without losing their protective edge.

- Thanks to their polyimide-based or silicone composite base, they stay stable under both AC and DC loads.

Low Thermal Resistance: A Key to Effective LED Lighting Management

When it comes to LED setups, managing heat isn’t optional—it’s survival.- Low thermal impedance allows rapid heat transfer from the LED chip to the heatsink.

- This means longer LED lifespan and consistent brightness over time.

- It also reduces color shifting caused by overheating—keeping whites white and blues blue.

Pairing low thermal resistance with strong electrical insulation makes these sheets indispensable for next-gen lighting systems.

Good Mechanical Strength Coupled with Flexibility for Various Applications

- Tensile strength: Withstands pull forces during installation without tearing or deforming.

- Compression resilience: Maintains shape under pressure—perfect for clamping between components.

- Flexibility: Bends easily around curves or tight corners; no cracking or peeling.

- Works great across sectors:Consumer electronics like laptops and phones、Automotive ECUs and battery modules、Telecom base stations where vibration is constant.

- Compatible with automated assembly lines thanks to its tear-resistant yet pliable nature.

Competitive Pricing with Custom Material Formulation Capabilities

You want performance? Check. You want value? Double check.- Manufacturers now offer custom blends tailored by application—whether you're after higher dielectric strength, lower thickness, or better flame retardancy.

- Bulk pricing options make it affordable even at scale, so startups and giants alike get access.

- Some brands even provide engineering support during prototyping stages—saving time on trial-and-error sourcing.

How to Select a High Thermal Conductivity Insulating Sheet

Choosing the right high thermal conductivity insulating sheet isn't just about specs—it's about keeping your gear cool, safe, and humming for the long haul.Operating Temperature Range Specification and Its Importance

- The operating temperature range tells you how hot things can get before your insulating sheet starts to break a sweat.

- If your device runs hotter than the sheet’s max rating? Expect warping, cracking, or worse—total thermal failure.

- Always match or exceed your system’s peak temps with the sheet's upper limit.

Essential Breakdown Voltage Insulation Requirements for Reliability

- Check the breakdown voltage rating—it’s basically the electric fence keeping current where it belongs.

- Go too low on this rating? Risk of arcing increases, leading to fried circuits or even fire hazards.

- For most mid-power applications, shoot for at least 5kV/mm breakdown strength.

Quality Control Inspection Procedures: Ensuring Performance and Stability

- Visual Inspection. Look out for air bubbles, warping, or discoloration; these can signal poor quality control during manufacturing.

- Thickness Consistency Testing. Uneven thickness = uneven heat transfer = uneven performance. Use micrometers at multiple points across each batch.

- Dielectric Strength Verification. Random samples tested under high voltage stress confirm whether they meet expected insulation resistance standards.

FAQs about High Thermal Conductivity Insulating Sheet

1. What makes a high thermal conductivity insulating sheet ideal for modern power systems?It combines speed of heat transfer with safety under voltage. The structure blends low thermal resistance characteristics observed in Aluminum nitride ceramic substrates and thermally conductive silicone rubber sheets, keeping circuits calm even under heavy load.

- High thermal conductivity performance metrics ensure efficient cooling for high power electronic components.

- Excellent electrical insulation properties provide safety where current surges may occur.

- Maintains mechanical flexibility and endurance through repeated heating cycles—vital for long-term reliability and stability.

2. In what way does material choice influence integrated circuit heat spreading efficiency?

A graphite-based thermal interface material flattens the temperature gradient like a gentle hand smoothing tension across an IC surface.

1️⃣ Surface treatment and coating options enhance contact with printed boards;

2️⃣ Even distribution prevents micro-hotspots, sustaining operational balance;

3️⃣ Quality control inspection procedures implemented ensure each layer meets precise dimensional tolerances before shipment.

Summary line: Selecting the right filler system converts energy peaks into harmony—protecting both performance and lifespan.

3. Why focus on breakdown voltage insulation requirements when sourcing sheets?

Each spark that could leap within a power amplifier enclosure is tamed by strong dielectric protection.

★ Breakdown voltage standards confirm the boundary between energy transfer and failure;

★ Flame retardancy safety certifications needed strengthen design compliance goals;

★ Environmental testing chambers available simulate stress so your insulating choice never falters in real use.

Thus, every volt finds its rightful path without crossing forbidden ground.

4. How do suppliers maintain consistency while offering custom designs at fair costs?

Certified ISO 9001 manufacturing facilities operate like orchestras tuned around precision instruments—thermal impedance measurement devices, automated optical inspection systems utilized daily to hold quality steady.

- Custom material formulation capabilities offered for special thicknesses or adhesive application techniques mean perfect alignment on assembly lines using automated dispensing equipment;

- Competitive pricing and payment terms available to ease scale-up without compromising tight specifications.

- Balance lies not just in managing cost—but in earning trust through repeatable perfection bound by science and craft alike.

English

English

usheenthermal

usheenthermal