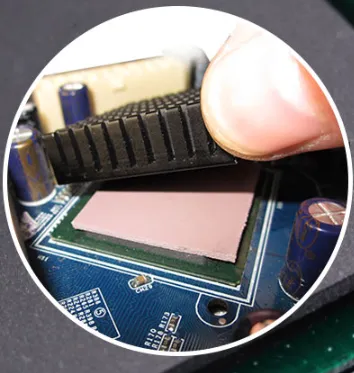

The double-sided adhesive is mainly because the product does not have a fixing device or is not convenient to fix. The double-sided adhesive can be used to fix the heat sink, and the IC and the heat sink are attached. There is no need to design a fixed structure.

Benefit: It can be used to fix the heat sink without the need to design another fixing structure.

Impact: The thermal conductivity will be worse, and the derivative coefficient will be much lower.

Single-sided adhesive for thermally conductive silicone pad:

The single-sided adhesive is mainly used to facilitate the installation and bonding of thermally conductive silicone. For example, a backlight uses a thermally conductive silicone with a size of 452 * 5.5 as a length, which is not easy to install. On the PCB, the other side is attached to the case.

Benefit: It can stick to the surface of the heater on one side. When the heat sink or the housing slides relatively during the assembly process, the thermally conductive silicone sheet will not shift position. Impact: The thermal conductivity will be lower, but it is better than the double-sided back effect. It is known from the above that whether the thermal silicone pad is provided with a single-sided adhesive or a double-sided adhesive, the thermal conductivity becomes low.

English

English

usheenthermal

usheenthermal