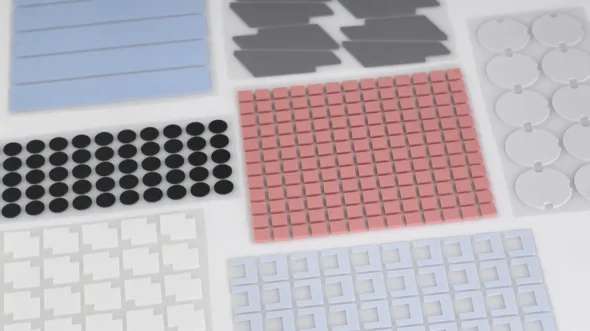

Thermally conductive silicone film is a gap-filled thermal pad made of silicone oil as the base material and added insulating, temperature-resistant, and thermally conductive materials. It has the characteristics of high thermal conductivity, low interface thermal resistance, insulation, and compressibility. Because of its softer hardness, it can realize a smaller thermal resistance under low pressure conditions, and at the same time eliminates the air between the contact surfaces and fully fills the rough surface between the contact surfaces to improve the heat conduction effect of the contact surfaces. Because of the good filling effect of the thermally conductive silicone sheet, it can effectively conduct the heat of the heat source to the shell, and the thermal conductive silicone pad has good compressibility and elasticity, and can serve as a shock-absorbing pad.

The thermal conductive silicone pad has high thermal conductivity, its texture is soft and elastic, which can effectively fill the gap between the two, so that heat can be quickly transferred to the outside through the thermal conductive silicone film. The thermal conductive silicone film developed and produced by Shengyuan New Materials has a thermal conductivity of 1 -12W/MK, the product has passed the 1000-hour reliability test, and the oil output rate is controllable. Welcome to consult.

English

English

usheenthermal

usheenthermal