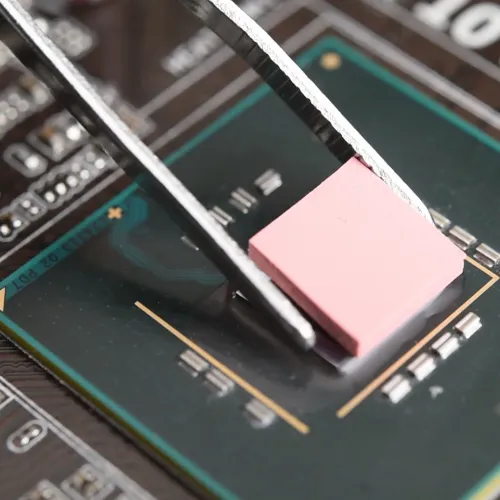

As an excellent interface gap filling thermal conductive material, thermal silicone pad is generally used in the gap between the heat source and the heat dissipation module to eliminate the air in the gap, reduce the contact thermal resistance, and improve the heat transfer efficiency.Sheen's thermal silicone pad also can alternative Laird' thermal material.

Thermal conductivity is a parameter to measure the thermal conductivity of thermal silicone pad. The higher the thermal conductivity of the thermally conductive film, the better the thermal conductivity. At the same time, its price and its influence are proportional to the relationship between the two. Thermally conductive silicone film has many parameters, except for thermal conductivity. In addition to the coefficient, its own thermal resistance is also an important parameter, because the higher the thermal resistance, the higher the resistance to heat transfer in the thermally conductive silicone sheet. This is why the two types of thermally conductive silicone have other parameters in addition to thermal resistance, thermal silicone pad with low thermal resistance, its thermal conductivity is better.

English

English

usheenthermal

usheenthermal