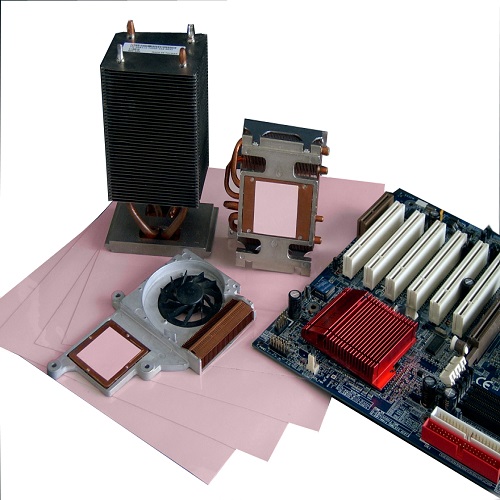

Thermal silicone pad is a common thermal conductive gap filling material. Thermal silicone pad is a gap-filling thermally conductive gasket made of silicone resin as the base material and added with temperature-resistant and thermally conductive materials. It has high thermal conductivity and low thermal conductivity. Interface thermal resistance, insulation, compressibility and other properties, because of its soft hardness, it can show a small thermal resistance under low pressure, while eliminating the air between the contact surfaces and fully filling the gap between the contact surfaces The rough surface improves the heat conduction effect of the contact surface.

With the development of science and technology, the performance of various products is getting higher and higher, which leads to the higher heat dissipation performance required by the product. The thermal conductivity of the Thermal silicone pad sold on the market is generally within 1-6W, but it cannot meet the heat dissipation requirements of the product, so A thermally conductive gap filler with a higher thermal conductivity is required.

Dongguan Sheen Electronic Technology Co., Ltd. is a high-tech enterprise with 14 years of experience in R&D and production of thermally conductive materials. Its SF Thermal silicone pad is the company's main product, with a thermal conductivity of 12W and passed 1000 hours of reliability testing. R & D and production experience, welcome to consult.

English

English

usheenthermal

usheenthermal