The heat generation intensity of intelligent driving high-performance chips far exceeds that of ordinary consumer-grade chips: A certain L4-level autonomous driving chip can process 80 trillion operations per second, with a power consumption as high as 300W, equivalent to the output power of a household microwave oven. If this heat cannot be dissipated in a timely manner, the core temperature of the chip will exceed the safe threshold of 105℃ within 3 minutes, directly leading to a 200ms increase in the processing delay of lidar point cloud data (enough for the vehicle to travel an additional 3 meters), a 12% decrease in the accuracy of neural network model inference (which may misjudge the type of obstacles), and an automatic 30% frequency reduction in computing power after 1 hour of continuous operation (equivalent to the "brain" suddenly becoming dull).

Traditional heat dissipation solutions are completely ineffective here: Silicone pads (with a thermal conductivity of 3-5W/MK) are like "insulating cotton" wrapping the chip, and the rigid contact of metal heat sinks will produce gaps due to vibration. At this point, graphene thermal pads and boron nitride thermal pads, which have both high thermal conductivity and high resilience, really come into play and become the key to solving this problem.

Graphene Thermal Pad: Creating an "Ultra-Fast Heat Dissipation Channel" for the Core Area of the Chip

Graphene thermal pads, with their high thermal conductivity, lay an "ultra-fast heat dissipation channel" for the core heating area of the chip. Its thermal conductivity of 70W/MK has shown amazing strength in a car company's actual test: it only takes 12 seconds to reduce the core temperature of the chip from 102℃ to 85℃. In a continuous 4-hour high-load test (simulating complex urban road conditions), the temperature fluctuation does not exceed 3℃, which can completely avoid decision-making errors caused by "thermal drift".At the same time, the 25% compression rebound rate allows it to perfectly fill the 0.1-0.5mm gap between the chip and the heat sink fins - if there is air in these gaps, the thermal resistance will increase by 300%, and the nano-scale bumps on the surface of the pad can completely interlock with the micro-pits on the surface of the component to ensure unimpeded heat conduction.

In the vibration test simulating vehicle bumps (frequency 20-200Hz), it can maintain 98% fit, while traditional pads will have a 0.2mm gap at 150Hz. A commercial vehicle company reported that after using this pad, the repair rate of chip-related faults decreased by 62%.

Boron Nitride Thermal Pad: "Insulating and Heat Dissipating Guard" Around the Chip

Although the thermal conductivity of boron nitride thermal pad (12-20W/MK) is lower than that of graphene, it has become the main heat dissipation force for the circuits around the chip due to its dual properties of "insulation + thermal conductivity".In the power management module, it solves the problem that "heat dissipation and insulation cannot be achieved at the same time": the volume resistivity is as high as 10¹⁴Ω・cm (equivalent to 100 times the insulation of air), which can avoid short circuits caused by the contact of metal heat sinks. At the same time, the thermal conductivity of 12-20W/MK can control the capacitor temperature below 70℃, far exceeding the 5W/MK of traditional insulating pads.

In the signal interface area, high-frequency signal channels such as lidar interfaces and camera interfaces of autonomous driving chips are most afraid of electromagnetic interference. The dielectric constant of boron nitride is only 4.0, which can avoid signal attenuation while dissipating heat. A test showed that after replacing the traditional mica sheet with it, the signal transmission bit error rate decreased from 0.3% to 0.01%.

In the cold and heat shock test from -40℃ to 125℃, the dimensional change rate of the boron nitride pad is less than 0.5%. In high-temperature environments such as near the engine compartment, it is more reliable than the graphene pad which is easy to oxidize.

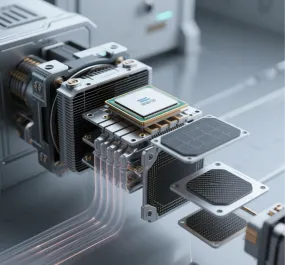

Dual Pad Collaboration: Building a "Three-Dimensional Heat Dissipation Protection Network" for the Chip

In practical applications, the two pads form a collaborative system of "core area + peripheral area": the graphene pad is close to the bare die of the chip (core heating area) and undertakes 70% of the heat dissipation task; the boron nitride pad covers the peripheral power management, signal interface and other areas, handling the remaining 30% of heat and providing insulation protection.A comparative test by an autonomous driving solution provider showed that this combined scheme improved the overall heat dissipation efficiency of the chip by 58%, and the cost was only 12% higher than that of the single graphene scheme (far lower than the all-graphene scheme). More importantly, it has passed the ISO 26262 functional safety certification, and in the ASIL-D level test (the highest safety level), there were no failure cases caused by heat dissipation.

English

English

usheenthermal

usheenthermal