Ordinary Silicone Pads: The "Roadblock" to Automotive Heat Dissipation

The automotive environment is extreme and complex, with temperature fluctuations ranging from -30°C to 60°C, accompanied by constant vibrations. Ordinary thermal conductive silicone pads show obvious shortcomings in such scenarios: on the one hand, they suffer from "silicone migration," where silicone components penetrate and contaminate the optical elements of the screen, causing light spots, shadows, and reducing display quality; on the other hand, they have poor adaptability, making it difficult to meet the precise thickness requirements of different-sized automotive screens, and they lack sufficient adhesion to handle assembly scenarios without applied pressure, ultimately affecting heat dissipation stability.

Dimensional Adaptability: The "Precision Technique" of Silicone-Free Thermal Pads

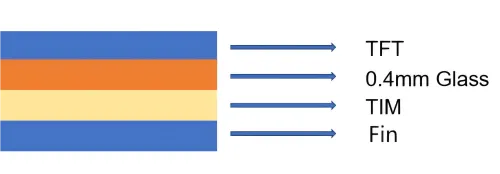

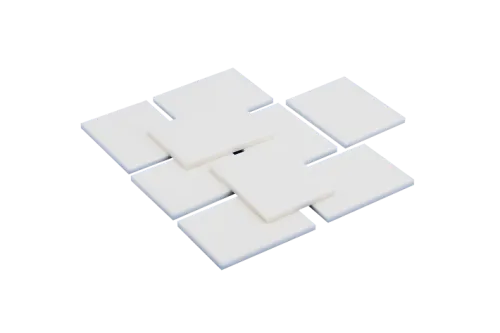

The core difference between 8-inch and 14-inch automotive screens regarding silicone-free thermal pads lies in the thickness selection. The internal space and assembly difficulty vary between screens, and improper pad thickness can lead to operational damage, fitting failure, and directly affect heat dissipation:For compact 8-inch central control screens with challenging assembly, a 0.5mm thick silicone-free thermal pad is an ideal choice. It not only fits into narrow spaces, avoiding damage from being too thick or reduced thermal adhesion from being too thin, but also relies on its own adhesion to fit onto fins without additional pressure from TIM materials, quickly conducting heat away from the driver IC. Products such as AF600 and AF800 offer this specification, meeting stringent requirements.

14-inch cockpit screens have more space, but the backlight module generates concentrated heat and requires compensation for larger gap tolerances. A pad thickness of 0.3mm to 0.5mm is suitable: use 0.3mm for small gaps to avoid assembly jams, and 0.5mm for large gaps or deviations to fill voids and ensure thermal conductivity. Tests show a 40% improvement in heat dissipation efficiency and an operational damage rate reduced to below 1%. Pads of this thickness also offer reliable adhesion, solving heat dissipation unevenness in large screens. The corresponding specifications of the AF800 series are widely used.

Hidden Advantages: The "Strong Support" for Automotive Stability

Beyond precise dimensional adaptability and preventing silicone migration, silicone-free thermal pads have two critical performance metrics in automotive scenarios that directly determine long-term screen stability:First, resistance to high and low temperatures. After cyclic testing between -40°C and 120°C, silicone-free pads do not easily become hard and crack, nor do they soften and lose integrity. The screen starts up stably even at -30°C, and the pad maintains stable thermal conductivity and adhesion under 60°C exposure, avoiding fitting failure due to extreme temperature changes.

Second, anti-aging properties. The design life of automotive screens is generally 8-10 years. Ordinary materials tend to age and fail within 3 years, with adhesion declining, leading to heat dissipation gaps. Silicone-free pads use polymer-based materials and special thermal conductive fillers. After 5000 hours of aging tests, they still maintain original performance,basically matching the screen's lifespan. Car owners avoid mid-term repairs and replacements, and automotive manufacturers can significantly reduce after-sales costs and complaint rates.

Conclusion: Choosing the Right Pad Provides "Dual Insurance" for Automotive Screens

For car owners, installing dimensionally adapted silicone-free thermal pads means the automotive screen won’t suffer from black screens or afterimages due to poor heat dissipation, and frequent costly repairs are avoided. For automotive manufacturers, it not only reduces pad damage and loss during assembly but also lowers post-production after-sales pressure. It also easily complies with stringent automotive electronics standards (such as ISO 16750 environmental resistance testing and IATF 16949 quality system requirements).Now, more and more automotive manufacturers are standardizing customized silicone-free thermal pads in new vehicles. For example, in certain new models, the 8-inch central control screen uniformly uses a 0.5mm ultra-thin high-adhesion version, while the 14-inch cockpit screen flexibly uses either 0.3mm or 0.5mm high thermal conductivity versions depending on the batch. In the six months since launch, screen failure complaint rates have dropped by 60%, and assembly efficiency has increased by 25%. Brands like Sheen, with mature experience in automotive thermal materials, have become the cooperation choice for many automotive manufacturers due to the precise adaptability and stable performance of their silicone-free thermal pads. Therefore, don’t overlook the details of thermal materials. A precisely adapted silicone-free pad not only solves assembly challenges but also ensures stable heat dissipation, making it the "invisible cornerstone" of long-term reliability for automotive display systems.

English

English

usheenthermal

usheenthermal