Analyzing the Root Causes: How the Traditional Three Materials Hinder Efficiency

The traditional three layers each have flaws: EVA film meets adhesion standards but is prone to aging under high temperatures; its light transmittance decreases by 10% over 5 years and its thermal resistance increases, hindering heat dissipation. The insulation board has a withstand voltage exceeding 10kV, meeting insulation requirements, but its low thermal conductivity coefficient causes heat buildup and temperature spikes in the cells. The encapsulant film provides sufficient waterproofing but has poor adhesion with other materials, easily forming bubbles that increase interfacial thermal resistance.The heat loss from these three stacked layers is significant. A 2m² PVT panel under standard illumination (1000W/m², total absorbed energy 2000W) experiences heat loss of 80 - 100W, accounting for 20% of the total absorbed energy. Industry data shows that for every 5°C decrease in cell temperature, power generation efficiency increases by 2.25%. This is precisely the breakthrough point for thermal pads.

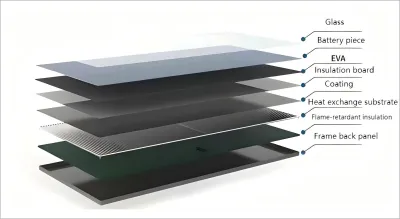

Just 1mm Thin: Triple Replacement Enabled by Performance

Thermal pads can achieve this replacement based on three key performance characteristics matching the requirements: A thermal conductivity ≥3.0W/(m·K), which is 10 times that of insulation boards and 5 times that of EVA, enabling rapid heat transfer. A dielectric strength ≥8kV/mm, higher than the 5kV/mm standard for PVT components, eliminating the need for an additional insulation layer. A Shore A hardness of 10 - 90A, offering good flexibility to conform to cells and heat absorption plates, eliminating bubbles and reducing interfacial thermal resistance to below 0.02°C·m²/W.It also functions as "one layer replacing three": its pressure-sensitive adhesive property replaces EVA (bonding strength ≥1.5MPa), its high insulation replaces the insulation board, and its weather resistance from -40°C to 120°C replaces the encapsulant film. It also reduces module thickness from 5 - 6mm to under 3mm, solving the heat dissipation problem.

Driving Efficiency Towards 85%: The Logic Behind Thermal-Electrical Deconstruction

The core of PVT comprehensive efficiency is "the proportion of effective utilization of the total absorbed solar energy," which must also deduct unavoidable thermal losses (environmental dissipation, material self-heating). Replacing with thermal pads optimizes heat dissipation, bringing two key improvements:First, improved electrical conversion efficiency: Cell temperature drops from 55 - 60°C to 48 - 52°C. Combined with the light transmittance of the thermal pad, power generation efficiency increases from the traditional 18% to 21%. A 200W module can generate 0.5 - 0.8 kWh more electricity per day. Second, increased proportion of utilizable thermal energy: Faster heat transfer increases the outlet water temperature of the heat absorption plate from 45 - 50°C to 52 - 55°C, raising the thermal energy utilization rate from the traditional 62% to 64%.

Correspondingly, the proportion of effectively utilized energy within the total absorbed energy of a traditional PVT system is 80%. After replacing with thermal pads, this proportion can increase to 85%. This optimization has been verified by third-party 1000-hour aging tests: the comprehensive efficiency decay rate after continuous operation was less than 2%, far superior to the 5% decay rate of traditional structures.

Benefits Beyond Efficiency: Value Through Cost Optimization

Thermal pads not only improve efficiency but also reduce costs: On the production side, what originally required 3 processes can now be done with one-step application of the thermal pad, saving over 30% in labor hours. It also reduces procurement costs for EVA and insulation boards, lowering comprehensive production costs by 15% - 20%. On the application side, the 30% reduction in module thickness makes them more suitable for scenarios like BIPV. The improved thermal efficiency also expands applications for hot water supply and heating, reducing the investment payback period from 8 - 10 years to 6 - 7 years.In fact, thermal pad products with thermal conductivity as high as 15W/(m·K) already exist on the market. For example, Sheen's 1mm ultra-thin high thermal conductivity series in this field utilizes customized filler ratios and process optimization. These maintain a dielectric strength ≥8kV/mm and a Shore A hardness of 40 - 60A, while also achieving low interfacial thermal resistance and long-term weather resistance. They have already demonstrated efficiency improvements in several PVT module pilot projects.

With the proliferation of such high-performance products, coupled with continued R&D by companies like Sheen on material application scenarios, PVT comprehensive efficiency is expected to accelerate towards 85%. This further unlocks the dual value of "photovoltaic power generation + solar thermal utilization," opening up broader space for the efficient use of new energy.

English

English

usheenthermal

usheenthermal