Why Is the Right Thermal Pad Critical?

In today's AI workloads, 4K gaming, and data visualization applications, GPU thermal power can easily exceed 250-400 watts. Unlike CPUs, which typically use liquid metal or thermal grease, GPUs feature multiple heat-generating components beyond the core—such as memory modules and power delivery units. These components cannot achieve perfect, flat contact with the heatsink. To prevent overheating, the thermal interface material (TIM) between the GPU chip, memory modules, and heatsink must efficiently transfer heat—and this is precisely where thermal pads come into play. These soft, compliant pads fill microscopic air gaps, effectively transferring heat from the components to the heatsink, ensuring they remain within safe operating temperatures.Thermal pads are robust elastomeric materials engineered to:

Fill microscopic voids between uneven surfaces;

Maintain uniform contact pressure;

Deliver high thermal conductivity and excellent electrical insulation.

Selecting the appropriate thermal pad not only enhances cooling efficiency but also ensures long-term stability, reduces fan noise, and extends the GPU's lifespan.

Key Parameters for Selecting GPU Thermal Pads

Choosing the right thermal pad isn't just about picking the one with the highest thermal conductivity or the most expensive option. It requires balancing multiple characteristics based on the GPU's specifications and the thermal pad's parameters. Let's delve into the key parameters:- Thermal Pad Thickness

- Thermal Conductivity (W/m·K)

- Flexibility and Compressibility

Sheen Technology's SP Series thermal phase-change materials remain solid at room temperature for easy assembly and handling. Upon reaching the phase-change temperature, they thermally soften into a liquid state with excellent wettability, effectively filling gaps between heat sinks and electronic components.

- Insulation

Sheen Technology's boron nitride-filled silicone thermal pads combine high thermal conductivity, superior insulation, and high resilience, making them an ideal choice for GPUs.

Sheen Technology Recommended GPU Thermal Pad Materials and Installation Techniques

| Material Type | Thermal Conductivity | Electrical Properties | Typical Applications |

| Silicone-based | 3–10 W/m·K | Insulating | Consumer GPUs, laptops |

| Boron Nitride (BN) | 8–15 W/m·K | Insulating | Insulating Gaming GPUs, industrial modules |

| Graphite | 10–20 W/m·K | Conductive | Mobile phones, laptops, and other portable devices |

Installation Techniques:

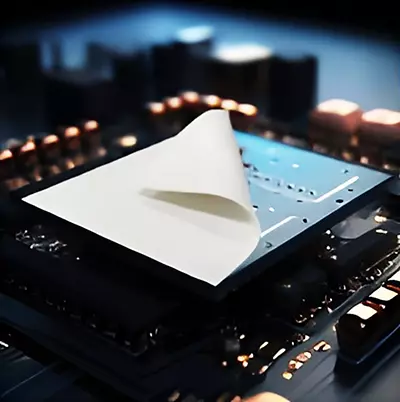

- Careful Removal: Gently open the graphics card, handling with care to avoid touching bonding surfaces.

- Surface Cleaning: Wipe the GPU core and heatsink with high-purity isopropyl alcohol and a lint-free cloth to remove all residual thermal paste and pads.

- Measure and Cut: Pre-cut new thermal pads to precisely match component dimensions and shapes. Sheen Technology offers custom die-cutting to any shape per client requirements.

- Precise Placement: Carefully align and position the thermal pads accurately over the memory chips and power supply modules.

- Reassembly: Apply even pressure to reinstall the heatsink, tightening screws in a cross pattern to ensure balanced force distribution.

At Sheen Technology, we understand that effective thermal management is a science. Through research into advanced fillers like boron nitride, we explore formulations that deliver exceptional thermal conductivity without compromising compressibility or long-term stability. We are committed to developing advanced thermal management solutions that integrate materials science with precision engineering.

By correctly matching specific hardware requirements with thermal pads, we significantly enhance product thermal performance and longevity, unlocking the full potential of your hardware.

English

English

usheenthermal

usheenthermal