Why Are Traditional Thermal Pads Falling Short?

In recent years, customers in the electronics and new energy industries have consistently reported recurring issues with traditional thermal pads.Despite their widespread use in thermal management, these materials often fail to meet modern application standards. Their primary limitations in use include:

- Poor adhesion: Most thermal pads require additional pressure or adhesive to establish stable contact between interfaces. Under complex vibration and thermal shock conditions, gaps easily form at the interface, creating additional contact thermal resistance.

- Aging: Some materials with low tackiness are prone to stress relaxation or substrate aging and brittleness under prolonged high-temperature environments, leading to reduced bonding integrity and subsequent degradation in heat dissipation performance.

- Insufficient Contact: Battery packs feature intricate internal structures with microscopic irregularities between heat sources and dissipation surfaces. Traditional materials lacking sufficient flexibility cannot perfectly fill these gaps, resulting in uneven thermal conduction and heat dissipation, significantly compromising cooling efficiency.

Sheen Technology Solutions: An Innovative Integration of Thermal Stability and Adhesion

Sheen Technology redefines the innovation standard for thermal interface materials with its next-generation products featuring high adhesion and thermal conductivity. Our R&D focuses on balancing thermal performance with mechanical integrity, merging efficient thermal conductivity and reliable structural bonding within a single material system to ensure long-term reliability in demanding environments.- High-Toughness Polymer Matrix: Utilizing specially modified silicone or acrylic systems, the material delivers enduring adhesion with superior fatigue and vibration resistance, maintaining tight bonding even in demanding conditions.

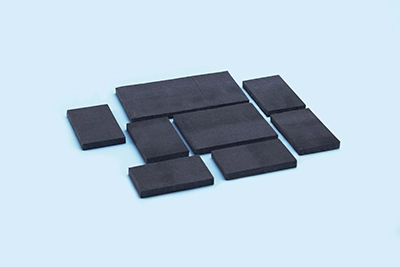

- Highly Filled Thermal Base Material: Carefully selected thermal fillers like alumina and boron nitride at various particle sizes create an efficient, stable 3D thermal network. The Sheen SF thermal silicone sheet series offers thermal conductivities ranging from 1-15 W/m·K, delivering comprehensive coverage, high performance, and sufficient thermal conductivity.

- Self-Adaptive Interface Properties: Sheen CSF series carbon fiber thermal pads feature ultra-high thermal conductivity, outstanding stability, and high compressibility. Combined with thermal gels and thermal greases, these products exhibit excellent wetting properties that fully fill uneven interfaces, effectively reducing contact thermal resistance.

Application Case: Transforming Pain Points into Highlights

In a recent client case, a power management company reported unstable temperature control when using standard silicone pads. After switching to Sheen Technology's high-adhesion thermal pad solution, our client achieved:- 35% increase in surface contact rate, enhancing overall heat dissipation efficiency.

- 20% reduction in temperature fluctuations, eliminating localized overheating.

- 18% extended product lifespan through improved thermal stability.

- Double-sided thermal tape for lightweight bonding applications.

- Thermal gel and thermal grease gap-filling materials for irregular components.

- High-performance foamed silicone for electric vehicle battery protection.

In today's fiercely competitive landscape of new technologies, traditional thermal pads can no longer meet the stringent demands for performance and reliability in modern electronic devices. Exceptional thermal management has become the key to making products stand out. By addressing core pain points such as poor adhesion, unstable heat transfer, and reduced battery life, Sheen Technology has set a new benchmark for thermal management materials.

If you are struggling with bonding and heat dissipation stability issues in thermal materials, feel free to contact Sheen Technology.

English

English

usheenthermal

usheenthermal