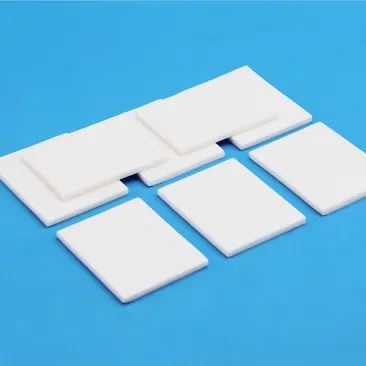

1. Introduction to Thermal Pads and Their Working Principle

A thermal pad is essentially a solid, flexible interface material that does not melt under normal operating conditions. Its core function is to establish an efficient heat flow channel between heat-generating components (such as chips) and heat sinks. The thermal pad conducts heat by filling the micro-gaps between the component and the heat sink, and softens slightly upon heating to improve adhesion while maintaining shape stability. Thermal pads are composite materials composed of two key parts:

-

Polymer Matrix: Typically made of elastomers such as silicone, giving the material a soft texture, compressibility, and electrical insulation. This matrix itself has been fully cross-linked and cured, forming a stable three-dimensional network structure.

-

Thermal Conductive Filler: A large amount of micron- or nano-sized ceramic powder (such as alumina, boron nitride) or metal oxides are uniformly filled into the matrix. These fillers are the true highways for heat transfer.

When the thermal pad is pressed between two surfaces, its soft properties allow it to perfectly fill microscopically uneven air gaps, expelling poor conductors of heat—air. Heat is emitted from the heat source and is rapidly conducted to the heat sink through a highly efficient thermally conductive filler network, thereby achieving cooling of the components.

2. Why do users perceive thermal pads as melting, and when does this melting phenomenon occur?

Users' misunderstanding of "melting thermal pads" typically stems from several situations:

-

Silicone oil precipitation: Both high-quality and low-quality thermal pads may release trace amounts of silicone oil under prolonged high temperatures, forming oil stains or wet residues, which can easily be mistaken for "melting." Sheen Technology's AF series silicone-free thermal pads use a special resin as the base material, eliminating low-molecular-weight siloxane volatilization and silicone oil precipitation.

-

Characteristics of phase change materials: Sheen Technology's SP series high-performance thermally conductive phase change materials are solid at room temperature. When the temperature reaches the phase change temperature (45℃-55℃), they begin to melt into a liquid state to better wet the interface. This is not a malfunction, but rather its normal operating state, although the change in appearance may be misleading.

.webp)

-

Permanent deformation (collapse): Under prolonged high temperatures and pressure, thermal pads may soften due to overheating, become excessively compressed and unable to rebound, losing their original thickness. This can also be mistaken for "melting."

Therefore, a high-quality thermal pad will never melt within its normal operating temperature range. Only when the operating temperature is far beyond its design limit at extreme high temperatures (e.g., >300℃) will a physical change similar to "melting" occur, releasing a large amount of silicone oil and losing the integrity of the product. However, in reality, the equipment at such operating temperatures may have already been damaged.

3. The Impact of Overheating on Thermal Pads

While high-quality thermal pads won't melt, exceeding their maximum continuous operating temperature (Sheen Technology SF series thermal pads operate between -50°C and 200°C) will cause irreversible damage, primarily manifested as:

-

Hardening and Embrittlement: The material loses elasticity and compressibility, becoming hard and brittle, creating air gaps, and easily cracking under vibration, leading to performance degradation.

-

Permanent Performance Degradation: Thermal degradation damages its internal structure, resulting in reduced heat transfer efficiency, a permanent decrease in thermal conductivity, and increased thermal resistance.

-

Silicone Oil Evaporation: Extreme temperatures may cause silicone oil separation and leakage, leading to loss of insulation and performance, potentially causing serious reliability issues in power electronics, power modules, and other products.

-

Accelerated Failure: Hardening, cracking, and performance degradation create a vicious cycle, posing long-term reliability risks and ultimately causing equipment overheating and damage.

When degradation occurs, the thermal pad loses its ability to maintain tight contact, causing a sharp increase in thermal resistance and triggering overheating, forming a self-reinforcing failure cycle.

4. How to Ensure Your Thermal Pads Don't Fail

To avoid thermal pad failure due to overheating, prevention and proper selection are key. Sheen Technology recommends following these steps:

-

Measure Thickness: Choose an appropriate thickness to avoid insufficient gap filling due to being too thin, or uneven pressure due to being too thick.

-

Confirm Temperature: Accurately assess the highest temperature of the heat source in your application and select a thermal pad with a temperature rating higher than this. For example, if the chip junction temperature is 110°C, choose a product with a long-term temperature resistance of at least 130°C.

-

Choose Special Materials: If your application experiences short-term temperature peaks, consider using phase change materials or high thermal conductivity gels, which are better suited to extreme conditions.

-

Choose a Reliable Brand: Choose brands like Sheen Technology that use high-purity, thermally stable substrates and high-quality fillers to fundamentally eliminate oil seepage and premature aging issues.

A high-quality thermal pad is designed to operate stably throughout its lifespan, not melt. The real risk lies in permanent performance degradation due to thermal degradation. By making scientific selections and trusting professional partners like Sheen Technology, you can completely eliminate concerns about "melting" and ensure your devices receive long-term, reliable "cool" protection.

At Sheen Technology, our materials scientists formulate thermal pads based on the core principle of delivering predictable performance under pressure. We use high-purity, thermally stable base polymers and advanced fillers to push the boundaries of temperature resistance and long-term reliability, providing reliable long-term performance for the following applications:

GPUs and AI accelerators

Electric vehicle battery packs and power modules

5G communication equipment

LED lighting modules

Industrial automation and power electronics equipment.

English

English

usheenthermal

usheenthermal