With the vigorous development of the LED lighting industry, especially in the recent years of continuous technological innovation, high-power LEDs have become more and more popular, and the heat generated by LEDs has also increased, and the temperature has become higher and higher. It is particularly important. Most LED lamps used to be coated with thermal conductive silicone grease on the PCB aluminum substrate and then fixed by screws or springs. In addition, the

thermally conductive silicone pad can also be attached between the PCB board and the heat sink and also fixed by screws or snap springs. In summary, the general thermally conductive material is difficult to play a role in both thermal conductivity and good adhesion to LEDs. The advent of

thermally conductive double-sided adhesive has completely solved this problem; at the same time, the convenience and excellent cost-effectiveness of

thermally conductive double-sided adhesive are also

thermal Double-sided tape is an important reason for the extensive use of LED lighting industry and LED TV.

A brief overview of the application of thermally conductive double-sided adhesive in the specific LED lamp industry.

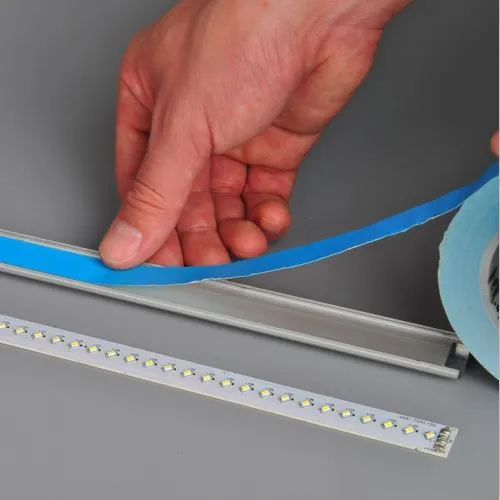

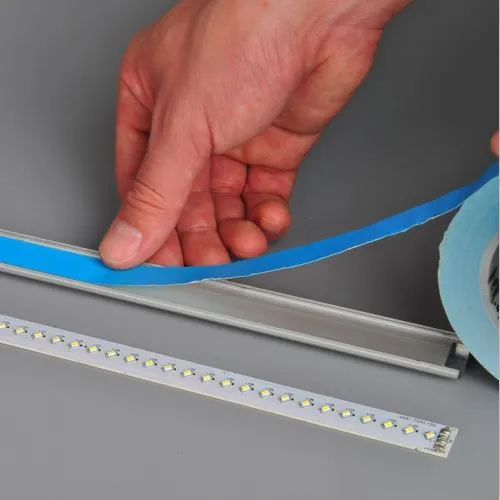

1. Application of

thermally conductive double-sided adhesive in LED fluorescent lamps

A thermally conductive double-sided adhesive is affixed between the PCB board of the LED fluorescent lamp and the heat-dissipating aluminum, and it can be pressed with a little force. The thermal conductivity effect is more significant than other thermal materials. At the same time, it is replaced by screws or springs, which is simple and convenient to use and is conducive to improving production efficiency.

2. Application of

thermally conductive double-sided adhesive in spotlights

Place the heat-conducting double-sided sticker between the spotlight PCB board and the heat sink, and press firmly, the heat sink is firmly fixed on the PCB board

English

English

usheenthermal

usheenthermal