What to Know About Thermal tape in Medical Devices

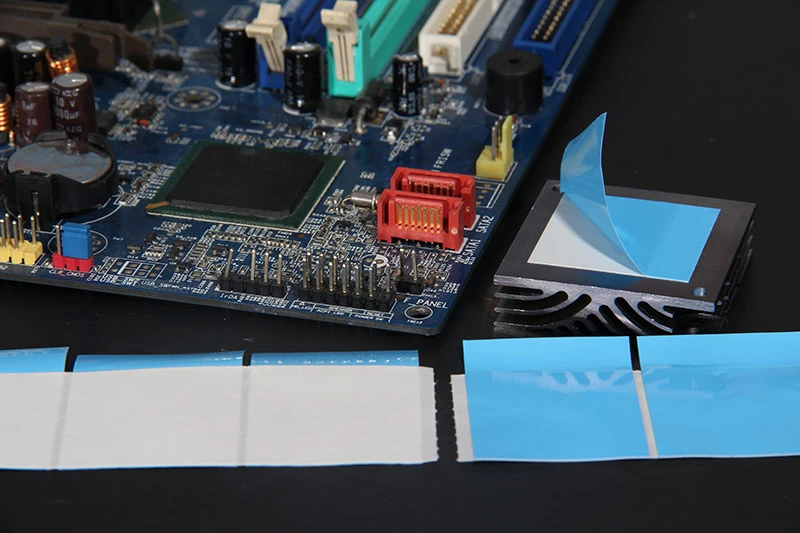

When you're dealing with circuit boards the size of a little finger and devices implanted directly into the human heart, heat dissipation isn't just a minor annoyance—it can be a critical factor determining the success or failure of a product. That's where medical devices thermal tape comes in. It's like an engineer's all-purpose tape, only safer. These amazing little things silently dissipate dangerous heat.

In 2023, the global thermal interface materials market reached $3.2 billion (source: Allied Market Research), driven by miniaturized electronics in the healthcare and wearable device sectors. What does this mean? If your product generates significant heat, it's best to implement effective heat dissipation measures immediately, rather than waiting until the product fails in actual use. Because nothing damages customer trust more than an accident report prominently displaying "equipment failure."

4 Key Benefits of Thermal Tape in Medical Devices

When it comes to medical gear, every detail counts. These four perks of using thermal tape in medical application can make or break device performance.Enhanced heat dissipation for electronic components

- Keeps internal temps under control—no more fried circuits during peak operation.

- Helps sensitive parts like sensors and chips stay cool even when things get heated.

- Works hand-in-hand with thermal management systems to boost overall stability.

Reliable adhesive bonding strength for secure applications

- Locks down components so they don’t wiggle loose over time.

- Maintains hold across different surfaces—plastics, metals, you name it.

- Reduces the risk of rework or failure due to poor adhesion.

Excellent electrical insulation properties for device safety

Long story short? It keeps electricity where it's supposed to be—and outta places it shouldn’t go.Short bursts of current can wreck a perfectly good sensor or processor if there's no buffer in place. The right thermal tape medical solution not only moves heat but also acts as an invisible shield against shorts, helping ensure solid device safety, consistent uptime, and peace of mind during patient use or testing scenarios alike.

How Thermal Tape Enhances Device Performance

A thermal tape design isn't just about sticking things together—it's about keeping your devices cool, safe, and running like clockwork.Medical device thermal management: A critical need

- Medical gadgets aren’t just fancy tools—they’re lifelines. If they overheat, performance tanks and safety goes out the window.

- Medical devices thermal tape solution ensures heat is whisked away from sensitive electronics.

- These Thermal tape are crafted from high-thermal conductivity materials that pull heat toward cooler surfaces fast.

Power amplifier thermal control through superior adhesion

- Amplifiers get hot—fast.

- That’s where a smartly engineered Thermal tape steps up.

- It bonds tightly while allowing for clean removal if needed.

- With strong bonding strength, it keeps locked in place even under vibration or long-term use.

- Plus, its ability to conform to uneven surfaces makes it ideal for tight amplifier enclosures.

| Properties | Unit | SA406FG | SA408FG | Test Method |

| Thickness | mm | 0.15±0.02 | 0.20±0.02 | ASTM D374 |

| Peel Strength | - | 1.8kgf/25mm | 1.8kgf/25mm | PSTC-3 |

| Holding Power (1.0kg loading on 25mm*25mm@25℃) |

h | >48 | >48 | PSTC-7 |

| Holding Power (0.5kg loading on 25mm*25mm@80℃) |

h | >24 | >24 | - |

| Thermal Conductivity | W/m·K | >0.4 | >0.4 | ASTM D5470 |

| Operating Temp. | ℃ | -30~130 | -30~130 | - |

| Dielectric Strength (@AC) | kV/mm | >4 | >4 | ASTM D149 |

| RoHS | - | PASS | PASS | IEC 62321 |

| Halogen | - | PASS | PASS | EN14582 |

| REACH | - | PASS | PASS | EN14372 |

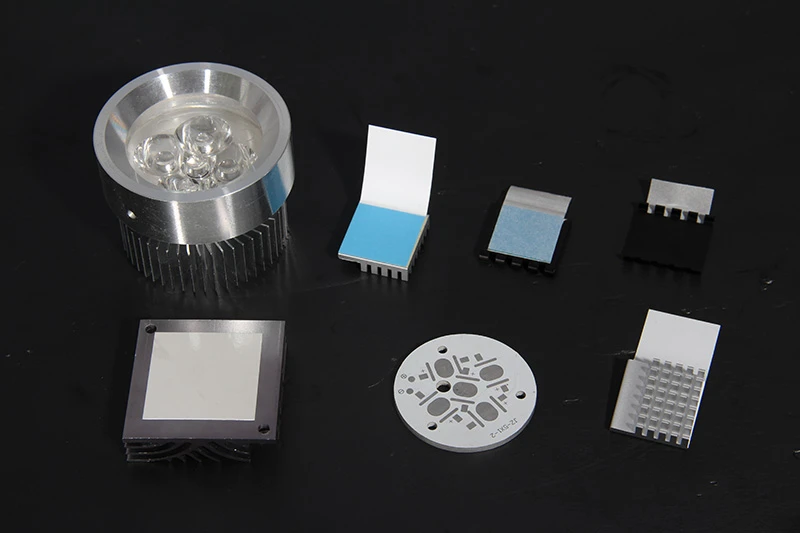

LED lighting thermal tape regulation benefits

- LEDs hate heat—it shortens lifespan faster than you'd think

- The secret sauce? A well-cut thermal tape hugs the baseplate snugly.

- These thermal tape offer excellent gap filling, ensuring there’s no air pocket acting as an insulator

How to choose the right thermal tape?

Choosing the right medical devices thermal tape solution means balancing safety, performance, and customization. Here's what really counts.RoHS-compliant material composition for safety

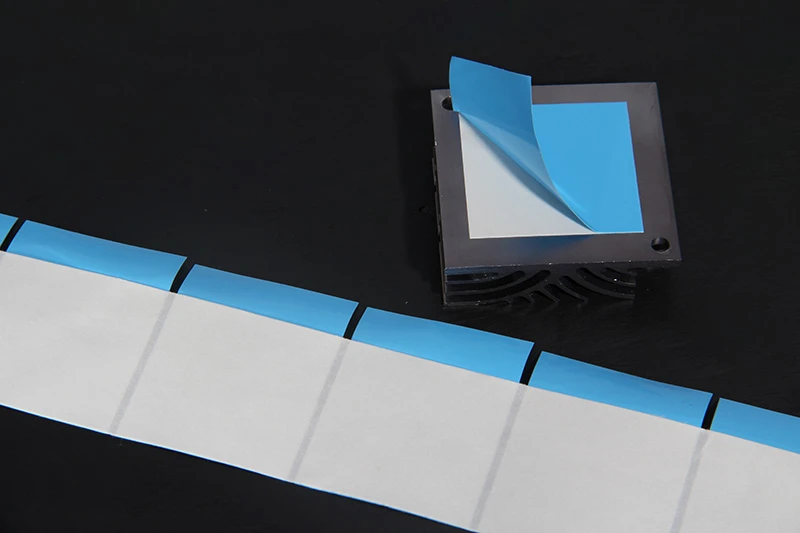

RoHS compliance isn't just a checkbox—it's a guarantee that your thermal interface materials won't compromise patient safety. Medical-grade devices demand non-toxic materials that align with global environmental standards. By using RoHS-certified thermal tape, you're not only protecting users but also ensuring regulatory acceptance across international markets.Custom adhesive layer thickness for varied applications

- Thin layers (0.1–0.3 mm) ideal for tight tolerance assemblies.

- Medium thickness (0.5–1 mm) balances flexibility and bonding strength.

- Thick layers (>1 mm) absorb vibration and accommodate uneven surfaces

Precision die cutting capabilities for optimal fit

- Tailored contours reduce waste during assembly

- Perfect alignment improves component contact

- Faster prototyping cycles

- Reduced manual trimming on production lines

From biocompatible adhesives to shape-perfect contours, every detail matters when selecting a medical devices thermal tape configuration that meets real-world demands—not just lab specs.

Sheen Electronic Technology supports these requirements through tailored engineering options across multiple device classes while ensuring compliance with evolving global safety norms like RoHS and UL certifications.

Cost vs Value: Thermal Tape in Medical Devices

Understanding the trade-offs between price and performance when choosing a medical devices thermal tape solution is key to reliable device design.Comparing Thermal tape and high-performance thermal compounds

- Thermal conductivity: Thermal tape offer predictable thermal conductivity, often around 0.8–3.0 W/m·K, while compounds can reach up to 8.0 W/m·K.

- Application method: Thermal tape are pre-cut and easy to apply, ideal for consistent assembly; compounds require manual application but conform better.

- Cost efficiency: Thermal tape reduce waste and labor time; however, high-performance pastes may save cost long-term by enhancing cooling.

Die cut thermal interfaces — Assessing long-term reliability and cost-effectiveness

Grouped advantages make die-cut interfaces appealing:Performance Gains

- Consistent thickness = improved thermal resistance

- Tailored shapes enhance surface contact and conformability

- Withstand sterilization cycles without losing adhesive strength

- Maintain bond under vibration, moisture, and aging stress

- Less rework during production = lower manufacturing costs

- Extended device life reduces warranty claims, boosting ROI

.webp)

.webp)

.webp)

| Metric | Thermal tape | Thermal Paste | Gap Fillers |

| Reusability | Low | Medium | High |

| Assembly Time | Fast | Slow | Moderate |

| Biocompatibility Compliance | High | Medium | Medium |

| Lifetime Reliability | Excellent | Good | Fair |

FAQs about medical devices Thermal tape

1. How does a thermal tape help in heat dissipation for fragile electronics? · A well-designed die cut thermal interface hugs the contours of components, from PCBs to LED lighting modules.

· Its high thermal conductivity performance swiftly moves heat away from stress-prone areas during medical device operation.· The Thermal tape cling firmly without harming delicate housings, reducing any risk of overheating that could compromise patient safety.

2. Why is RoHS compliance vital in Thermal tape used for healthcare technology?

RoHS compliant materials are free from harmful substances—lead, mercury, cadmium—that can jeopardize biomedical environments.

This ensures:

· Safer daily contact for staff and patients.

· Confidence in meeting long-term regulatory demands under ISO medical device standards and REACH regulations adherence.

3. Can tailored thickness improve bulk PCB thermal interface solutions?

Yes — customizing thickness allows exact fit across varying designs while keeping bonding strength intact even beneath intense power amplifier or LED array workloads.

Benefits bloom through:

· High repeat accuracy using automated die cutting machinery;

· Reduced waste thanks to precision tolerances;

4. Why opt for precision die-cutting capabilities for large orders of medical devices Thermal tape?

Precision shaping isn’t just neat—it eliminates installer guesswork.

Key values include:

· Fits intricate layouts without manual trimming mishaps;

· Harmonizes mounting consistency across thousands of units via laser cutting precision tolerances;

· Supported by experienced application engineering support tied to global distribution network availability, ensuring every Thermal tape arrives ready to protect lives and devices alike.

English

English

usheenthermal

usheenthermal